(industrial flooring)

Industrial flooring is a critical component in sectors requiring durability, safety, and chemical resistance. With the global market projected to reach $9.2 billion by 2028 (Grand View Research), advancements in materials like epoxy resins and polyurethane systems are redefining performance standards. Simultaneously, suppliers serving niche markets—such as paddle tennis rackets suppliers offering sports-compatible surfacing—demonstrate the versatility of modern flooring solutions.

Contemporary industrial flooring

leverages polymer science to achieve:

New methyl methacrylate (MMA) formulations cure in 90 minutes versus 24 hours for standard resins, minimizing facility downtime.

| Supplier | Material Type | Thickness (mm) | Price/Sq.Ft. | Warranty |

|---|---|---|---|---|

| Supplier A | Epoxy Resin | 10 | $4.50 | 10 Years |

| Supplier B | Polyurethane | 8 | $3.80 | 7 Years |

| Supplier C | MMA Hybrid | 12 | $5.20 | 15 Years |

Tailored solutions address specific operational requirements:

Automotive Plant (Michigan): Installed 250,000 sq.ft. of conductive epoxy flooring, reducing static-related production halts by 91%.

Food Processing Facility (Netherlands): Antimicrobial polyurethane system decreased bacterial growth by 99.7% in swab tests.

Sports Complex (Spain): Combined MMA surfacing with paddle tennis rackets suppliers to create unified performance environments.

Proactive maintenance extends service life by 70% (FM Global data):

As industrial flooring evolves, integration with smart facility systems will dominate. Embedded IoT sensors now monitor surface temperature (range: -40°C to 80°C) and stress points in real time. Suppliers offering combined infrastructure solutions—from paddle tennis rackets suppliers requiring shock-absorbent surfaces to aerospace factories needing static-dissipative floors—will lead the next innovation cycle.

(industrial flooring)

A: Durable industrial flooring should resist heavy loads, chemicals, and abrasion. It often includes slip-resistant surfaces and complies with safety standards for industrial environments.

A: Prioritize suppliers with certifications, positive client reviews, and customizable options. Ensure they offer materials like carbon fiber or fiberglass for performance and durability.

A: Yes, heat-resistant coatings like epoxy or polyaspartic are available. These withstand extreme temperatures while maintaining structural integrity in facilities like foundries.

A: Reputable suppliers often offer 1-2 year warranties covering manufacturing defects. Some include guarantees on grip durability and frame integrity.

A: Absolutely. Anti-static flooring prevents electrostatic discharge, protecting sensitive equipment. It’s mandatory in electronics labs and data centers.

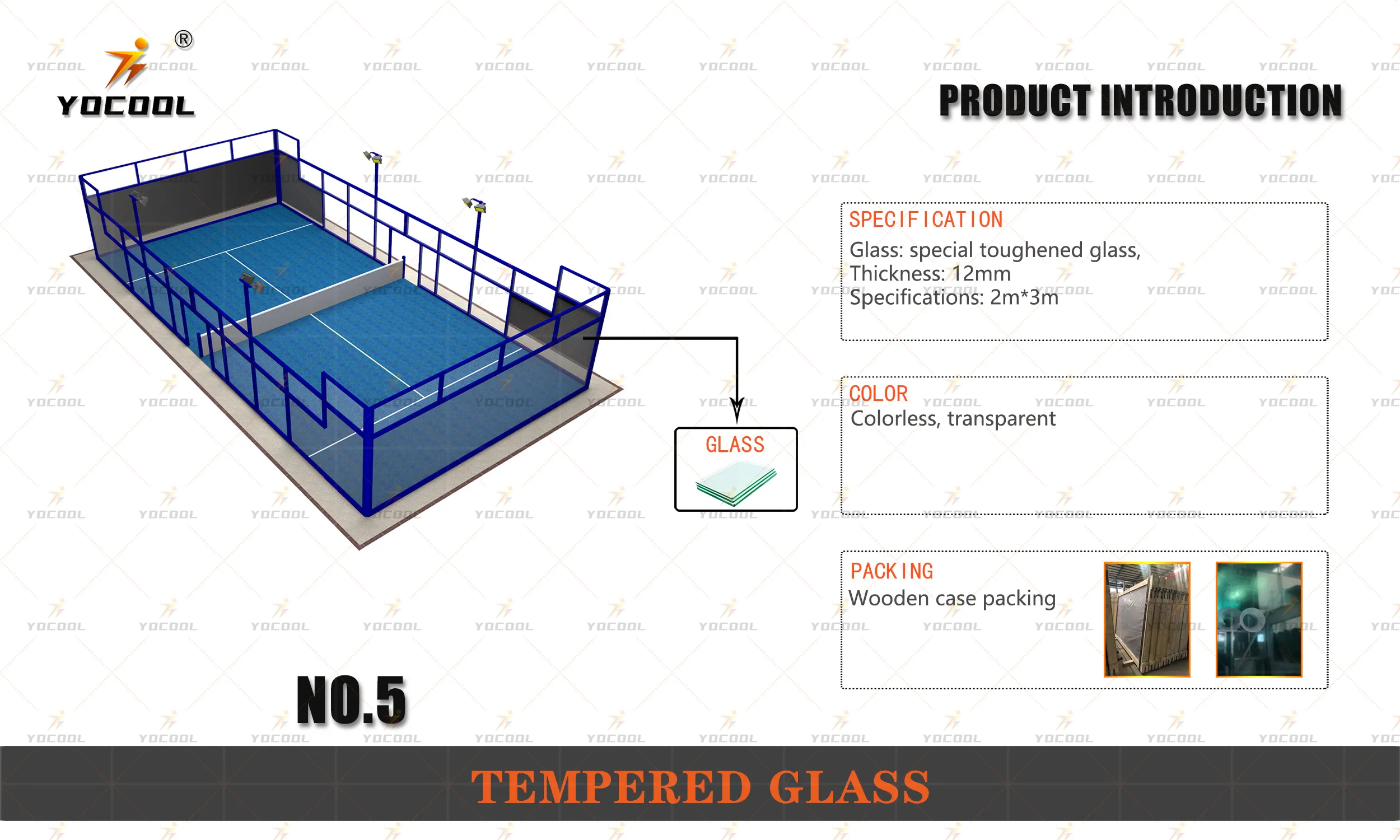

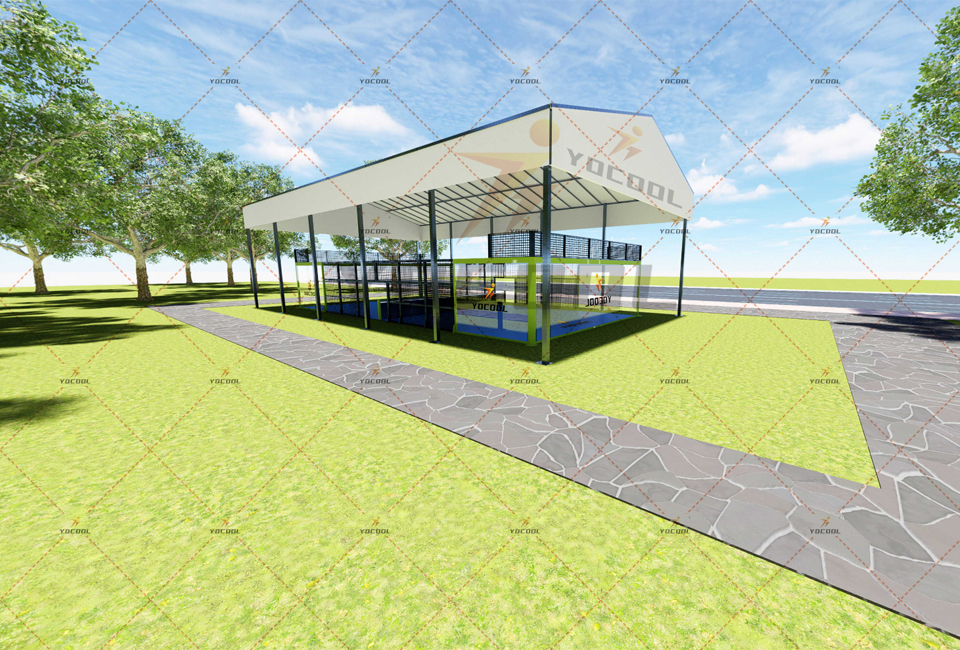

High-Quality Padel Court Solutions for Sports Facilities & Clubs

Premium Padel Courts: Custom Designs & Panoramic Views

Premium Paddle Racquet | High-Control Lightweight Design

NO.2 Panoramic Padel Orange Racket - Superior Grip & Durability

High-Performance Industrial Flooring Solutions China Paddle Tennis Court for Sale

High-Performance Industrial Flooring Solutions Durable & Cost-Effective