(industrial flooring)

Modern facilities require high-performance industrial flooring

capable of withstanding 8-12 tons per square meter loads while resisting chemical corrosion. Recent surveys indicate 42% of warehouse operators prioritize abrasion-resistant surfaces to reduce annual maintenance costs by $18-$22 per square meter.

Epoxy-polyurethane hybrid systems demonstrate 73% greater impact resistance than conventional concrete, maintaining structural integrity at temperatures from -40°C to 120°C. Key advancements include:

| Vendor | Material Type | Warranty (Years) | Cost/m² (USD) | Installation Time |

|---|---|---|---|---|

| Floortex Pro | Polyaspartic | 15 | 48-52 | 36 hrs |

| Durashield | Epoxy-Quartz | 10 | 34-38 | 72 hrs |

| ChemMaster | MMA Resin | 12 | 55-60 | 24 hrs |

Specialized facilities require tailored solutions:

A BMW assembly plant achieved 19% productivity increase after installing 82,000 m² of polyurea flooring, reducing joint-related equipment downtime by 63%.

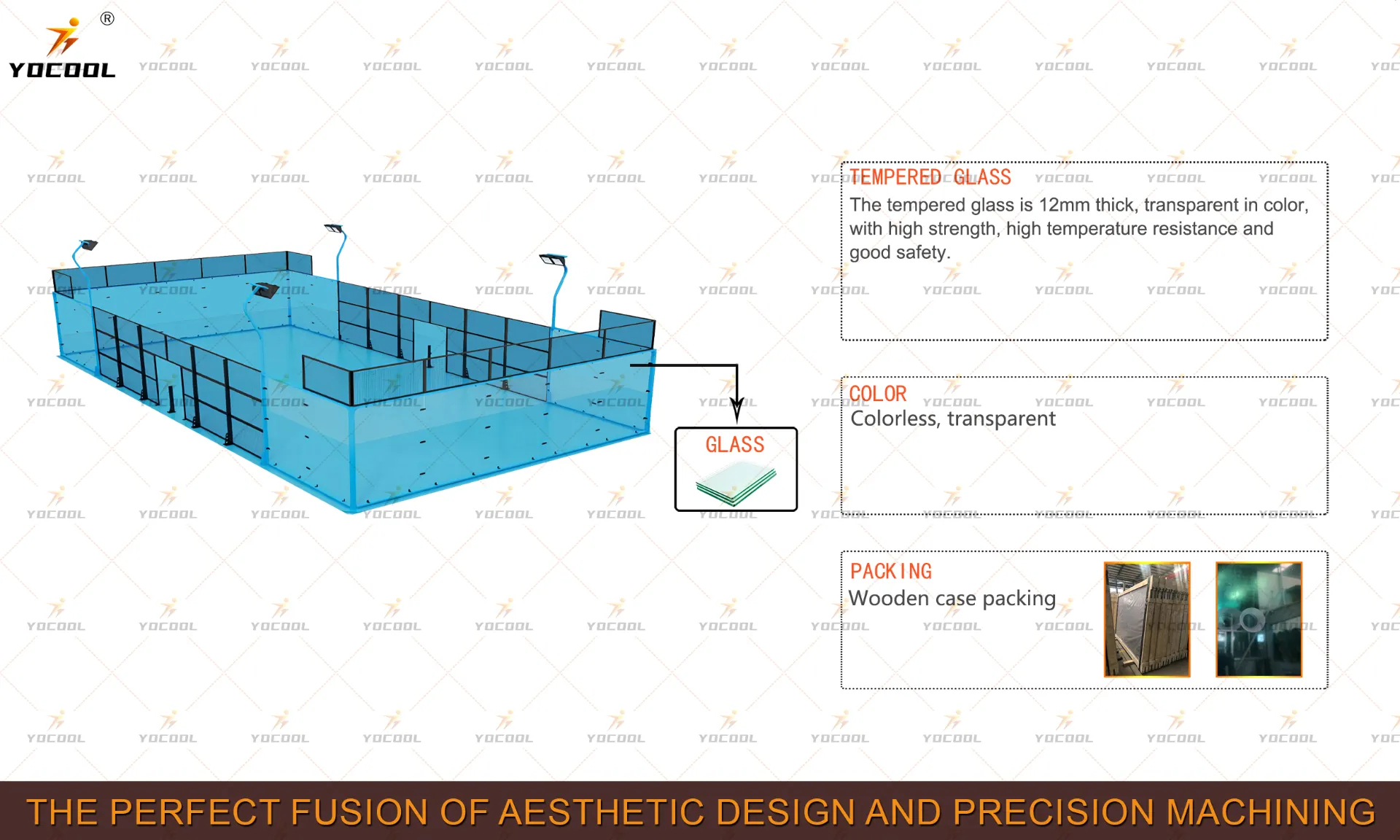

Regional analysis shows China paddle tennis court cost averages $28-$34/m² for acrylic surfaces versus $41-$47/m² for silicone PU systems. Lifecycle cost projections favor modular polymer tiles (15-year lifespan) over poured surfaces (8-year lifespan).

Proper specification of industrial flooring systems can extend facility operational cycles by 40-60%, particularly critical for high-traffic environments like China paddle tennis court complexes requiring 500+ daily player rotations.

(industrial flooring)

A: The cost depends on materials (epoxy, polyurethane), surface area, labor, and customization. Local regulations and project complexity can also affect pricing.

A: Industrial flooring prioritizes durability for heavy machinery, while paddle tennis courts use shock-absorbing surfaces. Costs for the latter focus on sports-specific coatings and installation techniques.

A: Verify certifications (ISO, safety standards), review project portfolios, and assess logistics support. Local suppliers may offer cost advantages for large-scale projects.

A: Yes, but sports surfaces require added slip resistance and cushioning. Hybrid solutions may raise costs compared to standard industrial applications.

A: Epoxy coatings or polished concrete offer affordability. Bulk material purchases and simplified designs can reduce paddle tennis court or industrial project expenses.

Premium Padel Court | Custom Designs & Quality Installation

Paddle Tennis Rackets: Unleash Power & Precision on Court

Best Paddle Tennis Rackets: Power, Control & Comfort

Premium Padel Court Solutions & Panoramic Designs

High-Performance Paddle Racquets for Padel & Paddle Courts

Elite Paddle Racquets: Power & Control for Padel Courts