Building the Future of Indoor Squash The Rise of Specialized Squash Court Factories

The indoor squash court market has witnessed substantial growth over recent years, fueled by the escalating interest in health and fitness along with the increasing popularity of squash as a competitive sport. A significant part of this expansion is attributed to specialized squash court factories that focus on manufacturing high-quality courts tailored to meet the diverse requirements of clubs, schools, and recreational centers.

Building the Future of Indoor Squash The Rise of Specialized Squash Court Factories

One of the primary considerations in the design process involves selecting appropriate materials. For instance, the walls of a squash court must be constructed from durable materials like glass or plaster to withstand the impact of the ball and players. The flooring is equally important, and factories often recommend using hardwood or specialized synthetic surfaces designed to offer optimal traction and bounce. The acoustics within the court also play a vital role; thus, sound-absorbing materials are integrated into the design to enhance the playing experience by minimizing outside noise distractions.

Moreover, squash court factories are now leveraging technology in the construction process. Advanced CAD (Computer-Aided Design) software allows designers to create precise layouts and account for various specifications, ensuring that each court is built to exacting standards. Additionally, modern manufacturing techniques such as prefabrication contribute to reduced construction times and overall costs, making it more accessible for clubs and facilities to implement new courts.

As part of their offerings, many squash court factories also provide supplementary services, including installation, renovation, and ongoing maintenance support. This holistic approach not only streamlines the court-building process but also fosters long-term relationships with clients. Factories can ensure that their constructions remain in optimal condition, thus ensuring longevity and superior playability.

Another noteworthy aspect of these specialized factories is their commitment to sustainability. In an industry increasingly focused on environmental responsibility, many manufacturers are exploring eco-friendly materials and energy-efficient practices. From using sustainably sourced wood to implementing waste-reduction measures, these initiatives not only benefit the environment but can also attract environmentally-conscious clients.

In conclusion, the emergence of indoor squash court factories represents a significant evolution in the world of squash. By prioritizing quality, safety, and sustainability, these establishments are not just building courts; they are fostering a vibrant squash community. As interest in the sport continues to rise, the role of factories in constructing premier facilities will undoubtedly be pivotal in shaping the future of indoor squash. With each new court built, the sport becomes more accessible to enthusiasts around the globe, paving the way for a new generation of players.

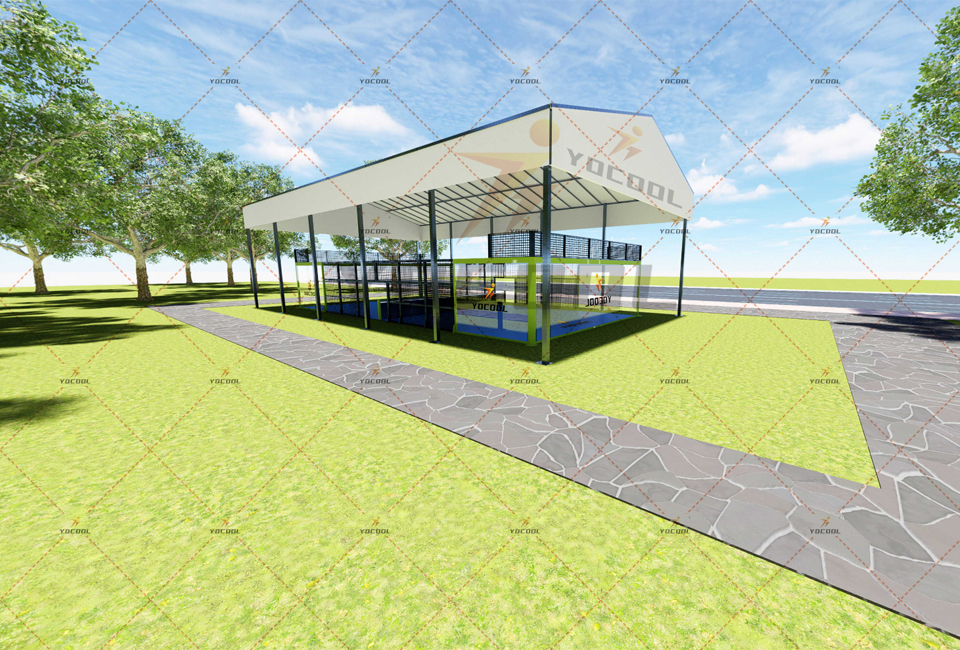

High-Performance Industrial Flooring Solutions China Paddle Tennis Court for Sale

High-Performance Industrial Flooring Solutions Durable & Cost-Effective

Homogeneous Transparent Floor – Durable & Stylish Rubber Floor Solutions

Premium Homogeneous Transparent Floor for Durable & Stylish Spaces Rubber Floor Solutions

Premium Sports Floor Solutions Durable PVC Sports Floor & Rubber Floor for Gyms

Durable Rubber Composite Floor Premium Rubber Floor & Mats Solutions