The Rise of Indoor Squash Court Factories A Modern Approach to Sports Infrastructure

In recent years, the popularity of squash has witnessed a significant resurgence worldwide. This can be attributed to the sport's fast pace, physical intensity, and the exciting indoor environment it provides. With this increasing demand, the establishment of specialized indoor squash court factories has emerged as a vital component in the sports infrastructure landscape. These factories cater not only to the needs of clubs and fitness centers but also provide a viable option for colleges, schools, and even private homes.

Understanding Indoor Squash Courts

Indoor squash courts are enclosed spaces designed specifically for playing squash. They are typically built with materials that enhance the playing experience, such as high-quality glass walls that allow spectators a clear view of the action, special flooring that absorbs impact and provides traction, and proper lighting that eliminates shadows and enhances visibility. A standard squash court measures 32 feet wide, 21 feet high, and 60 feet long, with precise measurements in all aspects to ensure compliance with international regulations.

The Factory Concept

Indoor squash court factories specialize in manufacturing modular squash courts that can be customized to meet various client needs. These factories utilize advanced technology in their production processes, leveraging prefabrication techniques that allow for quicker assembly and reduced on-site construction times. The modular approach not only streamlines the manufacturing process but also enables the production of courts that can fit diverse environments — from large sports complexes to smaller community centers.

Benefits of Indoor Squash Court Factories

1. Quality Assurance By centralizing production in factories, companies can maintain high standards for quality control. Each component, from the wall panels to the flooring, can be rigorously tested and manufactured under ideal conditions. This assurance translates to better durability and improved player satisfaction.

2. Cost-Effectiveness The efficiencies gained in a factory setting often lead to lower costs for both manufacturers and consumers. By producing courts in bulk, factories can reduce material waste and optimize production runs, passing these savings onto customers. Additionally, the quick assembly processes minimize labor costs on the installation side.

3. Customization Each squash court can be tailored to reflect the needs of the specific facility. Whether it’s adjusting the color of the walls, incorporating branding for a sports team, or configuring courts in non-standard spaces, flexibility is one of the standout features of factory-produced courts.

4. Sustainability Many modern factories are turning towards sustainable practices. This includes using eco-friendly materials and energy-efficient processes during production. As sports facilities increasingly prioritize environmental concerns, this aspect can be a significant selling point.

5. Expansion of Accessibility The proliferation of indoor squash courts created by these factories makes the sport more accessible to a wide audience. By being able to establish courts in remote areas, schools, and fitness centers, the factories play a vital role in introducing the sport to new players and fostering a love for squash.

Challenges and Future Prospects

While indoor squash court factories present numerous advantages, they also face challenges, including fluctuating material costs and the need to adapt to changing consumer preferences. Moreover, as the global focus shifts towards more holistic fitness approaches, court manufacturers need to consider multi-use constructions that can accommodate various sports.

The future, however, looks promising. As interest in squash continues to grow, particularly among younger generations, the increasing number of health-conscious individuals and the rise of sports tourism signal a bright runway for indoor squash court factories. With ongoing innovations in technology and materials, these factories are set to revolutionize how squash courts are designed, constructed, and maintained.

Conclusion

Indoor squash court factories are playing a crucial role in the evolution of sports infrastructure. Their ability to deliver high-quality, cost-effective, and customizable options is meeting the demands of a growing sport. Whether it’s for competitive players or casual enthusiasts, the courts produced in these factories are paving the way for a flourishing squash community, ultimately enriching the world of indoor sports. As new trends and technologies emerge, the industry's adaptability will only enhance its capacity to promote this dynamic and engaging sport.

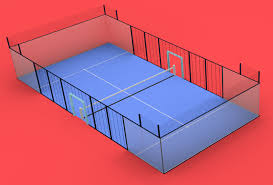

High-Performance Industrial Flooring Solutions China Paddle Tennis Court for Sale

High-Performance Industrial Flooring Solutions Durable & Cost-Effective

Homogeneous Transparent Floor – Durable & Stylish Rubber Floor Solutions

Premium Homogeneous Transparent Floor for Durable & Stylish Spaces Rubber Floor Solutions

Premium Sports Floor Solutions Durable PVC Sports Floor & Rubber Floor for Gyms

Durable Rubber Composite Floor Premium Rubber Floor & Mats Solutions