Essential Equipment Needed for Squash Manufacturers

Squash, an exhilarating sport requiring agility and precision, has gained immense popularity worldwide. As the demand for high-quality squash equipment surges, manufacturers must invest in advanced technology and machinery to produce top-notch products. This article explores the essential equipment needed for squash manufacturers, highlighting how each piece of machinery contributes to the overall production process.

1. Composite Material Preparation Machines

The primary material used in creating squash rackets is usually a composite of graphite, fiberglass, and other lightweight materials. Manufacturers need specialized machines to handle these materials effectively. Equipment such as extruders and mixers are essential for preparing the composite materials, ensuring a uniform mix that can withstand the rigors of gameplay. These machines help create the ideal properties for flexibility, strength, and weight, which are crucial for performance.

Molding is a critical step in squash racket production. Molding machines, particularly those utilizing injection molding technology, are utilized to create the racket frames. This process requires precise temperature control and pressure application to form the racket's shape. High-quality molding machines ensure the consistency and durability of each racket, with innovative designs enabling the production of different frame shapes and sizes to cater to various player preferences.

3. Curing Ovens

Once the composite materials are molded, they need to be cured to set the shape and enhance durability. Curing ovens play a pivotal role in this process. These ovens provide controlled heating that allows for the proper chemical reaction of the resins used in the composite materials. Effective curing ensures that the rackets maintain their integrity under stress, providing players with a reliable and robust tool on the court.

4. Stringing Machines

Stringing is an art in itself, and for squash rackets, it requires precision and expertise. Manufacturers should invest in high-quality stringing machines that can handle various types of strings while ensuring optimal tension. These machines enhance production efficiency, allowing employees to focus on quality control and other value-adding activities. Stringing machines equipped with digital interfaces can provide greater accuracy in string tension, catering to the preferences of different players.

5. Finishing Equipment

After the rackets are molded and strung, they must undergo finishing processes. This stage includes sanding, painting, and applying protective coatings. Finishing equipment, such as sanders and spray booths, ensures that the rackets have a smooth, appealing finish while maintaining durability against wear and tear. Additionally, UV curing machines may be used to expedite the drying process of paint and coatings, allowing for faster production turnaround.

6. Quality Control Instruments

Maintaining high quality is essential for any manufacturer, especially in the sporting goods industry. Quality control instruments are vital for testing the strength, weight, and balance of the finished rackets. Devices such as torque gauges, balance scales, and material testing machines help ensure that every product adheres to specified standards. By conducting thorough quality checks, manufacturers can prevent defects that could compromise player performance.

7. Packaging Machines

Once the rackets pass quality control, they need to be packaged properly for shipping and retail. Automatic packaging machines streamline this final stage, ensuring that each racket is securely wrapped and labeled. Efficient packaging not only protects the products during transit but also enhances the customer experience when they purchase the product. Custom packaging machines can also be tailored to the branding needs of the manufacturer, making the product stand out in a competitive market.

Conclusion

The realm of squash manufacturing is both dynamic and challenging, necessitating a comprehensive understanding of the equipment required to produce quality products. From composite material preparation to quality control and packaging, each piece of machinery plays a critical role in the overall production process. By investing in modern technology and equipment, squash manufacturers can improve efficiency, ensure quality, and ultimately meet the growing demand for premium squash gear. As the sport continues to flourish, the manufacturers that embrace technological advancements will undoubtedly have a competitive edge in the market.

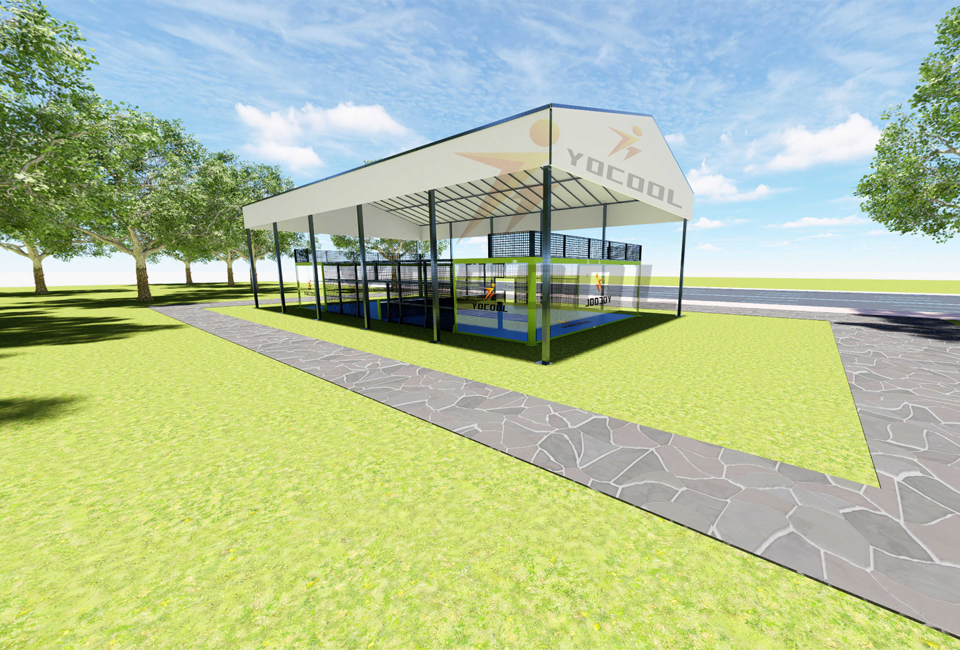

High-Performance Industrial Flooring Solutions China Paddle Tennis Court for Sale

High-Performance Industrial Flooring Solutions Durable & Cost-Effective

Homogeneous Transparent Floor – Durable & Stylish Rubber Floor Solutions

Premium Homogeneous Transparent Floor for Durable & Stylish Spaces Rubber Floor Solutions

Premium Sports Floor Solutions Durable PVC Sports Floor & Rubber Floor for Gyms

Durable Rubber Composite Floor Premium Rubber Floor & Mats Solutions