Equipment Needed for Squash Manufacturers An Overview

The production of squash, whether for culinary purposes or as a concentrated drink, involves a carefully orchestrated process that requires specific equipment. Squash manufacturers need to invest in various types of machinery to ensure the quality, efficiency, and safety of their products. This article explores the essential equipment required in squash manufacturing.

1. Fruit Washing and Sorting Equipment

The first step in squash production involves the thorough washing and sorting of fruits, primarily squash varieties. Cleanliness is paramount, as it prevents contamination and ensures a high-quality final product. Equipment such as fruit washing machines and sorting conveyors automate this initial stage, enabling manufacturers to process large volumes of fruit efficiently and maintain hygiene standards.

2. Crushing and Grinding Machines

Once the fruit is cleaned, the next step is to extract juice and puree. This requires crushing and grinding machines capable of breaking down the fruit's fibrous structure. High-capacity crushers and grinders can significantly speed up this process while ensuring a consistent texture, which is crucial for the preservation of flavor and quality in the final product.

3. Juice Extractors

For those manufacturers focused on creating juice-based squash, industrial juice extractors are essential. These machines efficiently extract juice from the fruit while minimizing waste. There are several types of extractors, including centrifugal and cold press models, each suited for different kinds of fruit. Choosing the right extractor ensures maximum yield and preserves the juice's natural flavors.

To enhance the shelf life of squash products, pasteurization is often necessary. This process involves heating the juice to a specific temperature for a set duration to kill harmful microorganisms. Continuous pasteurizers or batch pasteurizers are popular choices among manufacturers, allowing for effective heat treatment while maintaining the juice's quality.

5. Mixing and Blending Equipment

After pasteurization, squash concentrate is often mixed with sweeteners, flavors, and preservatives. Mixing and blending machines enable manufacturers to achieve a homogenous mixture quickly. These machines must be adaptable to accommodate various recipes and ingredient ratios, ensuring consistent product quality.

6. Filling and Packaging Machines

Once the squash is prepared, it needs to be filled into containers and packaged for sale. Automatic filling machines increase efficiency and reduce the risk of spillage during the bottling process. Following filling, labeling and packaging machines ensure that the products are accurately labeled and securely packaged, ready for distribution.

7. Quality Control Equipment

Throughout the manufacturing process, quality control is vital. Testing equipment for checking pH levels, sugar content, and microbial counts helps maintain product standards. Investing in quality control technology allows manufacturers to monitor their products closely and make necessary adjustments, ensuring customer satisfaction.

In conclusion, squash manufacturing requires a diverse range of specialized equipment to ensure efficiency, quality, and safety. From washing and sorting to filling and packing, each step involves specific machines designed to optimize production. By investing in the right equipment, squash manufacturers can enhance their output, meet market demands, and deliver high-quality products to consumers.

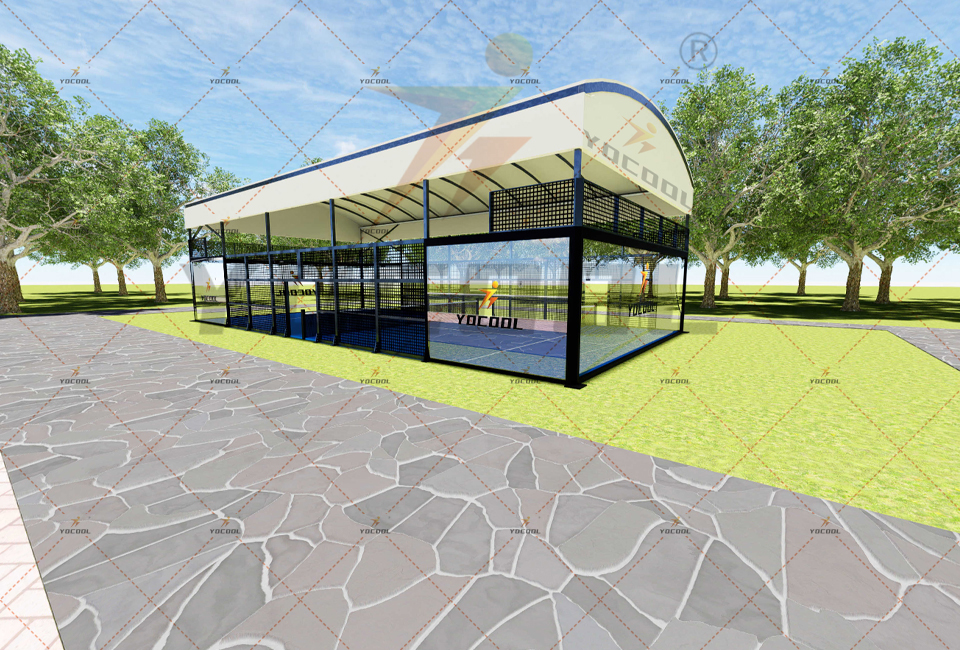

High-Performance Industrial Flooring Solutions China Paddle Tennis Court for Sale

High-Performance Industrial Flooring Solutions Durable & Cost-Effective

Homogeneous Transparent Floor – Durable & Stylish Rubber Floor Solutions

Premium Homogeneous Transparent Floor for Durable & Stylish Spaces Rubber Floor Solutions

Premium Sports Floor Solutions Durable PVC Sports Floor & Rubber Floor for Gyms

Durable Rubber Composite Floor Premium Rubber Floor & Mats Solutions