Equipment Needed for a Squash Factory

Setting up a squash production facility requires careful consideration of various types of equipment to ensure efficient and high-quality production. Squash, which can refer to both the sport where players use rackets and the vegetable typically consumed in meals, necessitates different machinery and tools. This article will focus on the equipment needed specifically for a squash processing factory, mainly concerned with the various types of squash vegetables that are cultivated, harvested, and processed for consumption.

1. Farming Equipment

The journey of squash from farm to table starts in the fields. Farming equipment is crucial for the successful cultivation of squash. Essential machinery includes tractors, tillers, and seeders. Tractors are required for land preparation, while tillers help in loosening the soil to create an ideal environment for squash seeds. Additionally, specialized seeders can optimize planting by ensuring correct spacing and depth for seed placement.

2. Harvesting Equipment

Once the squash is cultivated, harvesting is the next critical process. Hand tools like knives or clippers are commonly used for smaller operations, but larger factories may require mechanical harvesters that can efficiently gather squash from extensive fields. These harvesters minimize damage to the fruits and enhance productivity by speeding up the collection process.

After harvesting, squash needs to be transported to processing facilities without compromising its quality. Large containers or bins are used to transport the harvested squash. Forklifts and pallet jacks may also be necessary within the factory premises to move squash from one area to another efficiently. Ensuring that the squash stays fresh during transport is crucial; thus, refrigeration units can be included to preserve the vegetables during transit.

4. Processing Equipment

Once the squash reaches the processing facility, several machines are needed to prepare it for distribution. The first step generally involves washing machines to clean the squash, removing dirt and pesticide residues. Following this, cutting equipment such as slicers and dicers helps in preparing the squash in desired shapes for various products, whether they are sold whole or processed into purees.

For further processing, a blancher may be required. This equipment helps to preserve the color, flavor, and nutritional value by quickly cooking the squash in boiling water. Subsequently, vortex coolers are helpful to rapidly cool the blanched squash before packaging.

5. Packaging Equipment

Packaging is a vital step in the squash production line as it requires the protection of the product and information for the consumers. Various types of packaging equipment may be used, depending on the end product. For instance, vacuum sealers can ensure that squashes remain fresh for an extended period by removing air from the packaging. On the other hand, filling machines are beneficial for those looking to package squash in jars or cans. Labeling machines will also be necessary to provide product information and branding.

6. Quality Control Equipment

Quality control can't be overlooked in any production process. In a squash factory, various testing equipment may be needed to check the quality of the squash at different stages of processing. This might include pH meters, Brix refractometers (to measure sugar content), and humidity sensors to ensure that the final product meets safety standards and consumer expectations.

7. Storage Facilities

Lastly, proper storage facilities are essential for maintaining the quality of the squash, whether before processing or after packaging. Cold storage units can help in keeping the squash fresh longer, while dry storage locations may be used for products not requiring refrigeration.

Conclusion

In conclusion, opening a squash factory demands a range of specialized equipment to facilitate various stages of production, from farming to processing and packaging. Each piece of equipment plays a crucial role in ensuring the efficiency of the operation and the quality of the final product. It is imperative that manufacturers invest in the right tools to optimize their production processes while meeting the growing demand for squash in the market. With the proper setup, a squash factory can thrive, contributing significantly to the agricultural and food industry.

Premium Paddle Tennis Rackets for Every Court & Player

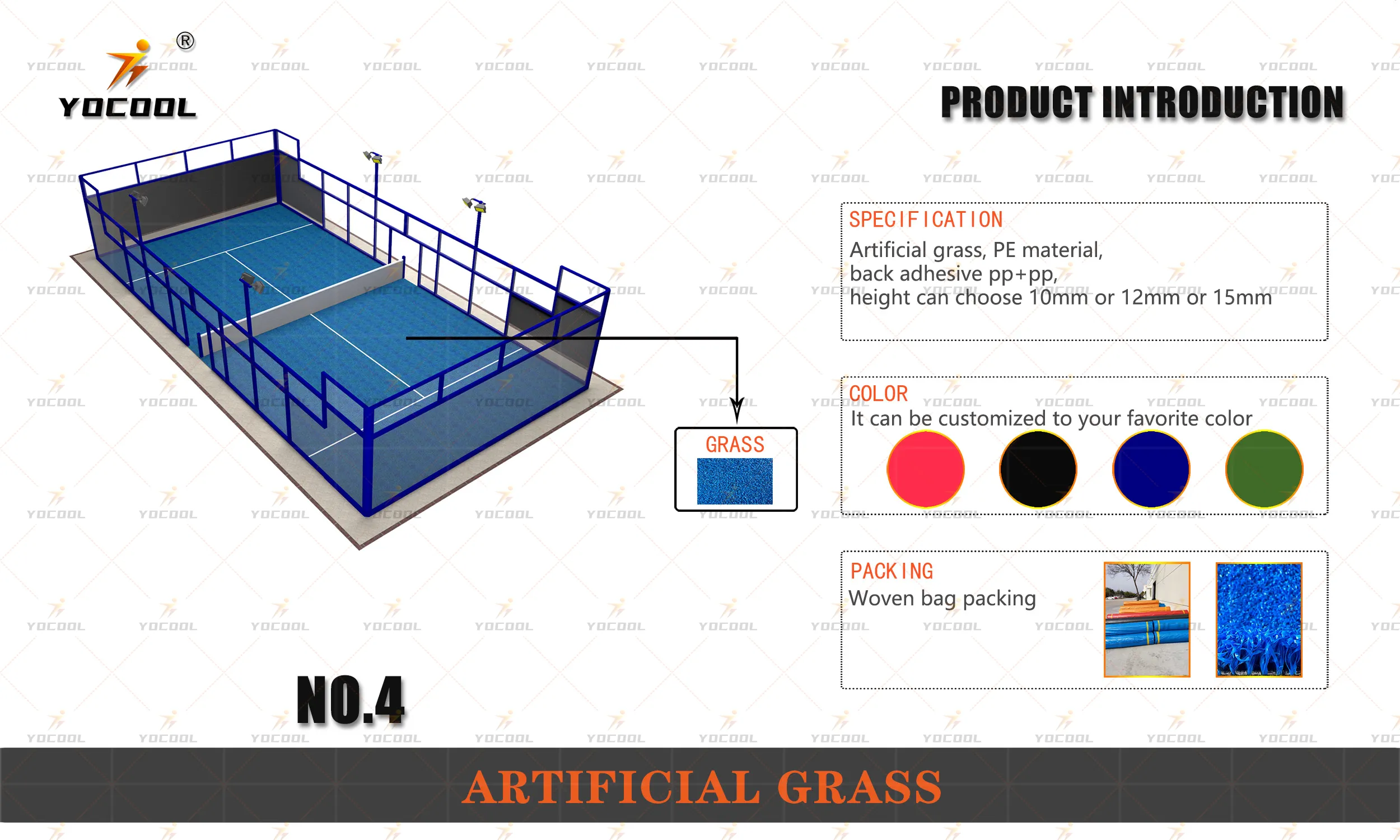

Premium Padel Courts: Expert Design & Installation Services

Premium Padel Courts: Panoramic Designs & Custom Builds

Premium Padel Court | Custom Designs & Quality Installation

Paddle Tennis Rackets: Unleash Power & Precision on Court

Best Paddle Tennis Rackets: Power, Control & Comfort