The Cost to Build a Padel Court Factory A Comprehensive Overview

Padel has become one of the fastest-growing sports in the world, attracting enthusiasts and players of all ages. As demand for courts increases, establishing a dedicated factory to manufacture padel courts presents a lucrative business opportunity. However, building such a facility involves a comprehensive understanding of costs, materials, labor, and market dynamics. This article explores the various factors that influence the cost of building a padel court factory.

Understanding the Market Demand

Before delving into the costs, it's essential to understand the market demand for padel courts. With millions of players globally, particularly in countries like Spain, Sweden, and Italy, the demand is steadily rising. Conducting thorough market research will help evaluate the potential customer base and competition. Understanding local preferences, prices, and available facilities will aid in formulating a business strategy that aligns with market needs.

Infrastructure and Land Costs

The cost of land is one of the most significant expenses when building a factory. The location will influence both the overall investment and operational costs. A site near major transportation links can reduce logistics costs, while proximity to potential customers may lower distribution expenses. Additionally, the zoning regulations and available utilities (water, electricity, and sewage) need to be factored into the cost. A decent plot of land suitable for industrial use can range anywhere from $50,000 to several million dollars, depending on the location.

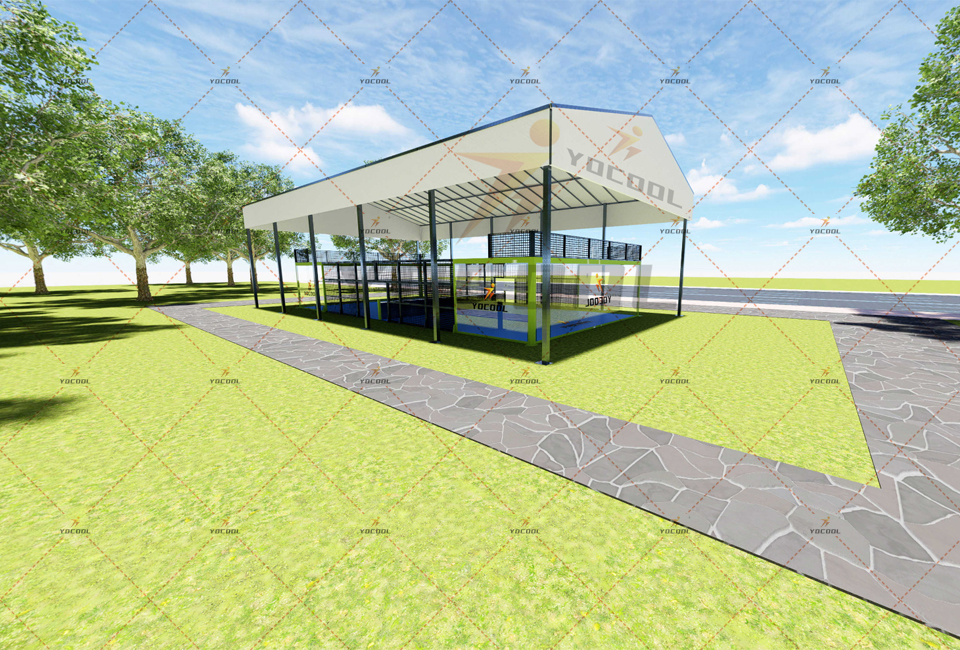

Construction Costs

Once the land is secured, construction costs come into play. This includes the costs associated with building the factory structure, which may vary significantly based on size and materials. A small-scale facility might cost around $200,000 to $500,000, while larger factories could surpass $1 million. Considerations include the type of materials used (steel frames, insulated panels, etc.), labor costs, and the complexity of designs.

Machinery and Equipment

A critical component of setting up a padel court factory is acquiring the necessary machinery and equipment for production. This includes machinery for cutting, shaping, and assembling court components (walls, flooring, nets). Depending on whether you opt for new or used equipment, costs can range from $100,000 to $500,000. Investing in high-quality machinery will improve production efficiency, reduce waste, and ensure that the final products meet safety and durability standards.

Staffing and Labor Costs

Labor costs are another vital factor in the overall expenditure. Hiring skilled workers, including engineers, designers, and factory operators, can be costly but essential for ensuring quality production. For a medium-sized factory, salaries might range from $200,000 to $500,000 annually, depending on location and expertise. Moreover, consider costs for training workers to uphold product standards and safety protocols, which can be an ongoing expense as the factory grows.

Operational Costs

Operational expenses, including utilities (electricity, water, gas), maintenance, and insurance, must also be correctly estimated. These ongoing costs can fluctuate based on production levels, but budgeting between $50,000 to $100,000 annually can offer a substantial safety net.

Marketing and Sales

Finally, once the factory is operational, effective marketing strategies are crucial for attracting customers and expanding the business. Budgeting for marketing campaigns, promotional materials, and attending industry events can also influence overall costs. Allocating around $20,000 to $50,000 per year for marketing might be a worthwhile investment to establish brand presence and customer loyalty.

Conclusion

Building a padel court factory involves significant financial commitment across various facets, including land acquisition, construction, labor, equipment, and operational costs. Successful ventures require meticulous planning and budgeting while also being adaptive to market changes. For investors and entrepreneurs, understanding these costs not only lays a foundation for the factory’s establishment but also positions it for long-term success in the burgeoning padel industry. As the sport continues to proliferate, investing in the right infrastructure can yield substantial returns and fulfill the rising demand for padel courts worldwide.

Premium Paddle Tennis Rackets for Every Court & Player

Premium Padel Courts: Expert Design & Installation Services

Premium Padel Courts: Panoramic Designs & Custom Builds

Premium Padel Court | Custom Designs & Quality Installation

Paddle Tennis Rackets: Unleash Power & Precision on Court

Best Paddle Tennis Rackets: Power, Control & Comfort