Building a Padel Court Factories, Processes, and Innovations

As the popularity of padel continues to soar globally, the demand for high-quality padel courts is increasing. To meet this growing need, specialized factories have emerged, designed to produce everything from the court structures to the surrounding amenities. In this article, we will explore the various aspects of building a padel court, focusing on the factories involved in the process, the materials used, and the technological innovations that are shaping the future of this sport.

The Rise of Padel

Padel, a racket sport that combines elements of tennis and squash, originated in Mexico in the 1960s and has gained tremendous traction in Europe and beyond. Its appeal lies in its accessibility, as the game is easy to learn and suitable for players of all ages and skill levels. As more people flock to padel courts, the need for high-quality facilities has become evident. This has led to the establishment of numerous factories specializing in the manufacture of padel courts.

Padel Court Factories An Overview

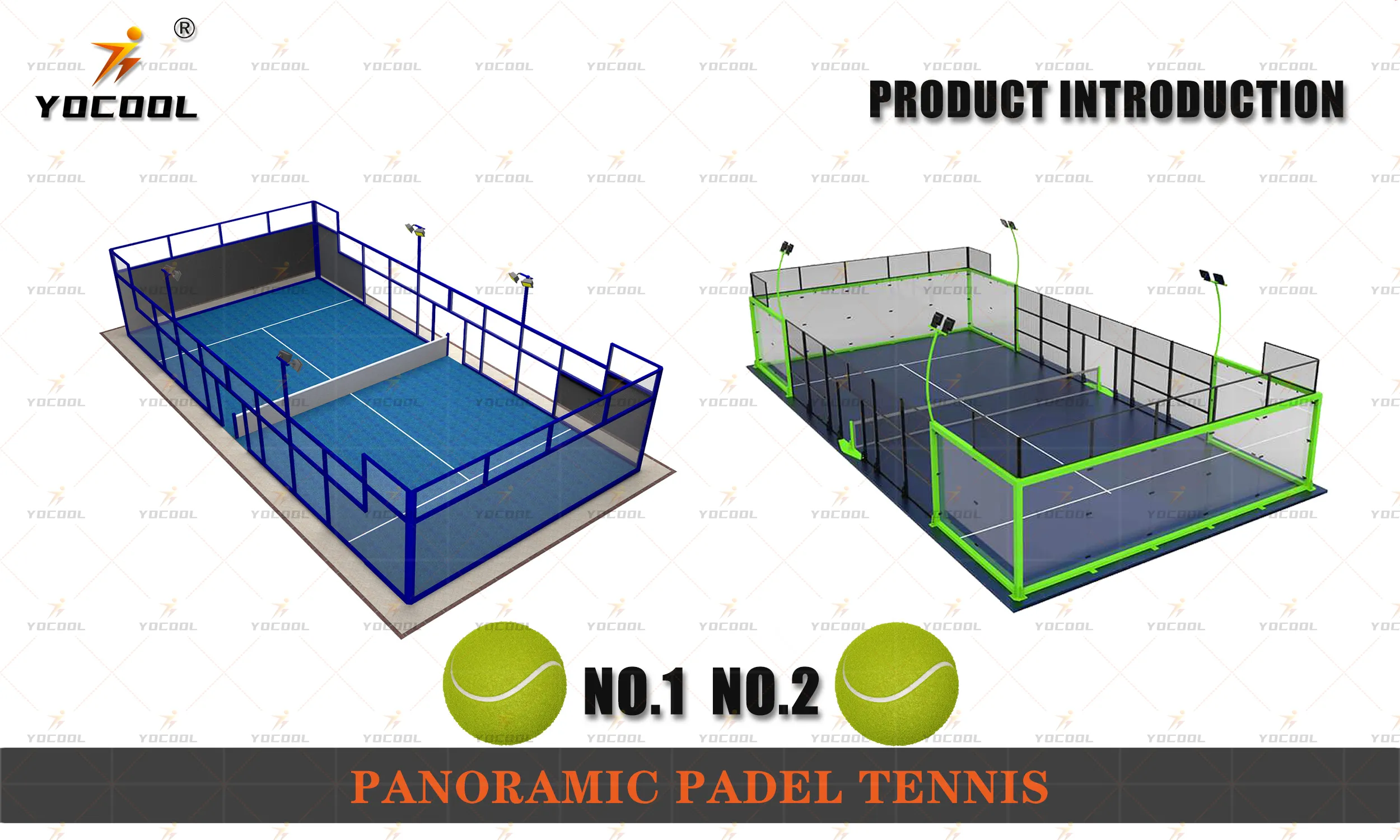

Factories for building padel courts typically focus on producing several key components the court structure, the glass walls, the flooring, and the lighting systems. These factories harness advanced technologies and innovative materials to ensure that each court meets international standards and provides an excellent experience for players.

1. Court Structure The primary frame of a padel court is usually made from galvanized steel, which ensures durability and resistance to weather elements. Some manufacturers also prioritize eco-friendly materials to appeal to an environmentally conscious market. The assemblies are prefabricated for quicker on-site installation, minimizing construction time.

2. Glass Walls The court's glass walls are a defining feature, enabling spectators to view the action from outside. Manufacturers utilize tempered or laminated glass to enhance safety and resilience. Innovations in glass technology have allowed for stronger and thinner panels, thereby increasing visibility and aesthetic appeal.

3. Flooring The choice of flooring can significantly impact gameplay. Factories produce various options, commonly including artificial turf or synthetic surfaces that provide optimal traction and comfort. These materials are often designed to be low-maintenance and weather-resistant, allowing for year-round play.

4. Lighting Systems Quality lighting is crucial for enhancing visibility during indoor and evening matches. Factories engineer specialized LED systems that not only illuminate the court adequately but also do so in an energy-efficient manner. These systems can include features such as adjustable brightness and color temperature, providing a tailored experience for players.

The Manufacturing Process

Building a padel court involves a systematic and efficient manufacturing process. Initially, designs are created based on the specific requirements of the client, including dimensions, materials, and budget. After finalizing the designs, the production phase begins with the fabrication of the steel frame, followed by glass panel production and flooring material preparation.

Once all components are ready, the court is shipped to the designated site. Installation teams, often composed of skilled technicians, assemble the court efficiently. This installation phase is essential and can generally be completed within a few days, ensuring clients can quickly start using their new facility.

Innovations and Future Trends

As with many industries, the padel court construction sector is continually evolving. Automation and robotics are beginning to play a significant role in the manufacturing processes, enhancing precision and reducing production costs. Additionally, sustainable practices are being adopted more widely, with many factories focusing on recyclable materials and eco-friendly manufacturing processes.

Moreover, the integration of smart technology is becoming a trend within padel courts, with the inclusion of features such as automated scoreboards and analytics systems that provide players and coaches with valuable performance data.

Conclusion

The construction of padel courts involves a comprehensive process that combines engineering, aesthetics, and innovation. Factories dedicated to this booming industry are at the forefront of creating state-of-the-art facilities that meet the rising global demand. As padel continues to grow in popularity, the future of padel court construction will likely be marked by further advancements in technology and sustainability, ensuring that this engaging sport is accessible and enjoyable for generations to come.

High-Performance Industrial Flooring Solutions China Paddle Tennis Court for Sale

High-Performance Industrial Flooring Solutions Durable & Cost-Effective

Homogeneous Transparent Floor – Durable & Stylish Rubber Floor Solutions

Premium Homogeneous Transparent Floor for Durable & Stylish Spaces Rubber Floor Solutions

Premium Sports Floor Solutions Durable PVC Sports Floor & Rubber Floor for Gyms

Durable Rubber Composite Floor Premium Rubber Floor & Mats Solutions