The Evolution and Importance of Badminton and Squash Court Factories

As sports continue to gain popularity globally, the demand for specialized facilities that cater to different athletic needs has surged. Among these, badminton and squash courts have emerged as two of the most sought-after spaces for athletes and enthusiasts alike. Behind the scenes, badminton and squash court factories play a pivotal role in the development of these essential sporting venues, ensuring that players have access to high-quality, durable, and safe environments to practice and compete.

Understanding the Manufacturing Process

Badminton and squash court factories dedicate themselves to the intricate process of designing and constructing courts that meet international standards. The manufacturing process begins with careful planning and engineering. Engineers and designers must consider various factors, including court dimensions, lighting, flooring materials, and wall constructions. For instance, a standard squash court measures 9.75 meters in width and 6.4 meters in height, while a badminton court has specific dimensions that cater to the fast-paced nature of the game.

Materials used in constructing these courts vary, but they typically incorporate high-quality wood, synthetic surfaces, or a combination of both. Popular choices for badminton courts include maple and birch wood, known for their resilience and excellent shock absorption, which helps reduce the risk of injury. Squash courts frequently utilize engineered wood or rubberized flooring to accommodate quick lateral movements and intense gameplay.

Technological Innovations

With the advancement of technology, badminton and squash court factories are increasingly adopting innovative methods to enhance the quality and efficiency of court production. For instance, the integration of computer-aided design (CAD) software allows manufacturers to visualize and simulate the court layout before actual construction begins. This helps in identifying potential challenges in the design and optimizing the overall functionality of the court.

Moreover, factories are now equipped with modern machinery that ensures precision in cutting and assembling court components. Automated systems for applying finishes and protective coatings have become commonplace, resulting in a more durable product that can withstand the rigors of regular play.

Safety and Standards Compliance

One of the most critical aspects that badminton and squash court factories must address is compliance with safety regulations and international standards set by organizations such as the Badminton World Federation (BWF) and the World Squash Federation (WSF). These governing bodies establish guidelines for court dimensions, surface type, and wall construction to ensure fair play and athlete safety. Factories are required to conduct rigorous testing of materials and construction methods to certify that their courts meet these standards.

In addition, regular maintenance and inspections are crucial for prolonging the life of the courts and ensuring player safety. Many factories have begun offering maintenance services, providing expertise on how to care for specialized flooring and lighting systems, thus extending the longevity of the courts they have installed.

The Growing Market

The market for badminton and squash courts has expanded significantly, driven by a growing interest in these sports globally. Many countries are investing in sports infrastructure, recognizing the health benefits and social cohesion that sports can foster. Factories are responding by increasing production capabilities and offering customized courts tailored to specific client needs, ranging from local clubs to elite training centers.

In conclusion, badminton and squash court factories are vital contributors to the world of sports. They ensure that athletes have access to well-designed, safe, and high-quality facilities, enabling them to perform at their best. As technology advances and the demand for sports facilities continues to grow, these factories will play an even more significant role in shaping the future of badminton and squash. As we look forward, fostering strong partnerships between factory manufacturers, sports organizations, and local communities will be essential in promoting and building thriving sports culture globally.

Premium Paddle Tennis Rackets for Every Court & Player

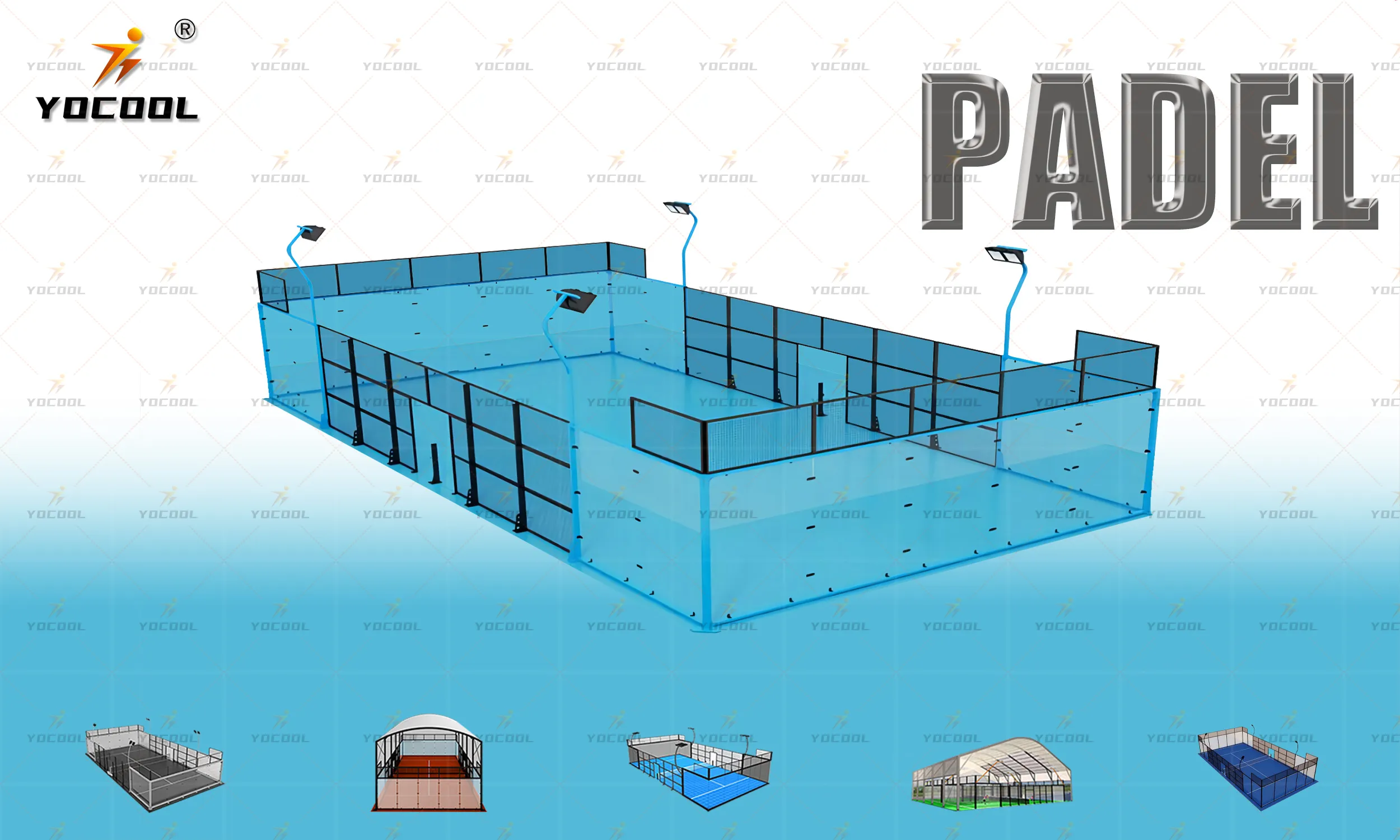

Premium Padel Courts: Expert Design & Installation Services

Premium Padel Courts: Panoramic Designs & Custom Builds

Premium Padel Court | Custom Designs & Quality Installation

Paddle Tennis Rackets: Unleash Power & Precision on Court

Best Paddle Tennis Rackets: Power, Control & Comfort