The Importance and Evolution of Squash Court Manufacturers

Squash, often hailed as one of the most intense racquet sports, has gained a massive following around the world. Played on four walls with a small rubber ball, the game demands skill, agility, and endurance. However, one of the key components that influences the quality of play is the squash court itself. This is where squash court manufacturers come into play, bridging the gap between innovation and tradition, ensuring that players have access to top-notch facilities.

The Role of Squash Court Manufacturers

Squash court manufacturers are responsible for designing, constructing, and maintaining the courts where players indulge in their passion for the sport. These manufacturers understand that different aspects of court design affect gameplay, including wall material, flooring, and overall dimensions. The perfect squash court is one that allows for optimal bounce and speed while providing safety and comfort for players.

One of the primary materials used in squash court construction is wood, specifically hardwoods like maple or oak. These materials offer durability and excellent ball response characteristics. However, manufacturers also explore synthetic materials that can enhance performance and reduce maintenance costs. Innovations in technology have led to the development of artificial surfaces that mimic the characteristics of wood while offering even further advantages, such as improved shock absorption.

Customization and Design

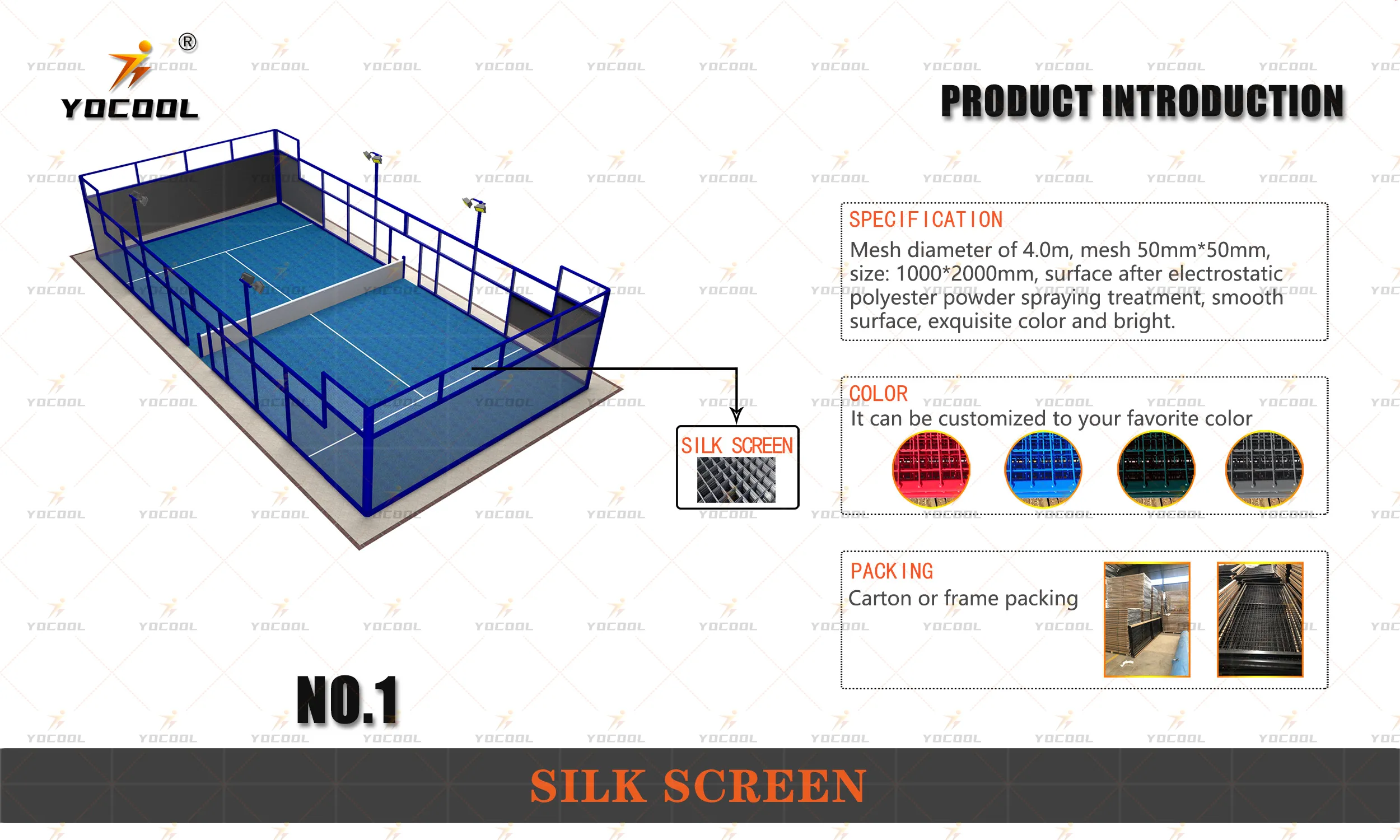

Every squash court is unique. Manufacturers must consider numerous factors, including space availability, intended use (club, school, or professional tournaments), and local regulations. Customization is key; courts can be tailored to meet specific requirements, such as incorporating glass walls for visibility in spectator areas or adding amenities such as seating and changing rooms.

Moreover, the aesthetic aspect is becoming increasingly important. Many manufacturers now offer a range of colors and finishes, allowing clubs to reflect their brand identities. As design trends shift toward more modern and stylish facilities, manufacturers are responding by integrating innovative designs that not only enhance functionality but also appeal to the visual senses.

Sustainability in Squash Court Manufacturing

As environmental concerns become more pressing, squash court manufacturers are increasingly incorporating sustainable practices into their operations. This includes sourcing materials from sustainable forests, using eco-friendly finishes, and opting for energy-efficient lighting systems. Manufacturers are now tasked with finding an equilibrium between producing high-quality courts and reducing their carbon footprint.

Additionally, maintenance practices have evolved. Proper care of squash courts is essential for longevity and performance. Manufacturers provide guidelines on maintaining surfaces, controlling humidity levels, and ensuring proper ventilation—all crucial factors for preserving the integrity of the court.

Innovative Technologies

The future of squash court manufacturing is poised for further evolution with the integration of smart technologies. Many manufacturers are beginning to experiment with smart court solutions, incorporating sensors that can monitor player performance and track game statistics. These innovations not only enrich the playing experience but also open new avenues for coaching and player development.

Furthermore, augmented reality (AR) and virtual reality (VR) technologies are surfacing in training environments. Players can simulate game scenarios, analyze their shots, and receive immediate feedback. Manufacturers who embrace these technologies position themselves at the forefront of the sport's modernization, catering to a new generation of tech-savvy athletes.

Conclusion

Squash court manufacturers play a pivotal role in the development and promotion of the sport. By prioritizing quality, customization, sustainable practices, and innovation, they ensure that both amateur and professional players enjoy the best possible courts to hone their skills. As the sport continues to evolve, it is essential for manufacturers to stay ahead of the curve, adopting new technologies and sustainability measures. In doing so, they not only contribute to the growth of squash but also to the overall wellbeing of the environment and the communities they serve. With a commitment to excellence, the future of squash court manufacturing promises to elevate the sport to new heights, ensuring that players enjoy the thrill of the game for generations to come.

Industrial Flooring Solutions for Factories & Racquetball Courts Safe & Durable

Premium Rubber Floor Mats Slip-Resistant, Durable & Easy Clean

Industrial Flooring Solutions for Outdoor Paddle Tennis Courts & Factories

Industrial Flooring Solutions Durable Padel Court Supplier & Installation

Rubber Composite Flooring Durable, Slip-Resistant Floor Mats

Premium PVC & Rubber Sports Flooring Shock Absorption, Slip Resistance