The Rise of Padel Behind the Scenes of Padel Ball Court Manufacturing

In recent years, padel has surged in popularity around the globe, captivating sports enthusiasts with its unique blend of tennis and squash elements. As this vibrant sport grows, the demand for high-quality facilities, particularly padel courts, increases significantly. Behind the scenes of this burgeoning trend is an intricate web of design, engineering, and manufacturing that goes into producing state-of-the-art padel ball courts. This article explores the journey of padel ball court factories and the key components that make these courts suitable for both recreational and professional play.

Understanding Padel

Before diving into the intricacies of padel court manufacturing, it's essential to understand what padel truly is. Padel is typically played in doubles on an enclosed court about one-third the size of a tennis court. The walls of the court are used in play, adding a strategic element that requires skill and finesse. This unique gameplay creates a growing interest among players of all skill levels, driving the need for appropriate facilities.

The Padel Court Manufacturing Process

1. Design and Planning The journey of creating a padel court begins with careful design and planning. Factories collaborate with architects, sports experts, and local communities to develop designs that not only meet international standards but also suit the specific needs of the intended location. This stage involves selecting materials, determining court dimensions, and ensuring that the design incorporates adequate visibility and accessibility.

2. Material Selection The choice of materials is crucial in the manufacturing process. Padel courts are typically made of a combination of glass, metal, and specialized synthetic surfaces. The glass used for the walls must be tempered for safety and resilience, while the metal frame needs to withstand weather elements. The playing surface is designed to provide optimal grip and cushion for players, reducing the risk of injury.

3. Fabrication Following the design phase, the actual fabrication of components begins. This step often takes place in a factory equipped with advanced machinery and tools. Precision is key, as even minor discrepancies can affect gameplay. Factories often employ skilled technicians who ensure that every piece adheres to the highest quality standards.

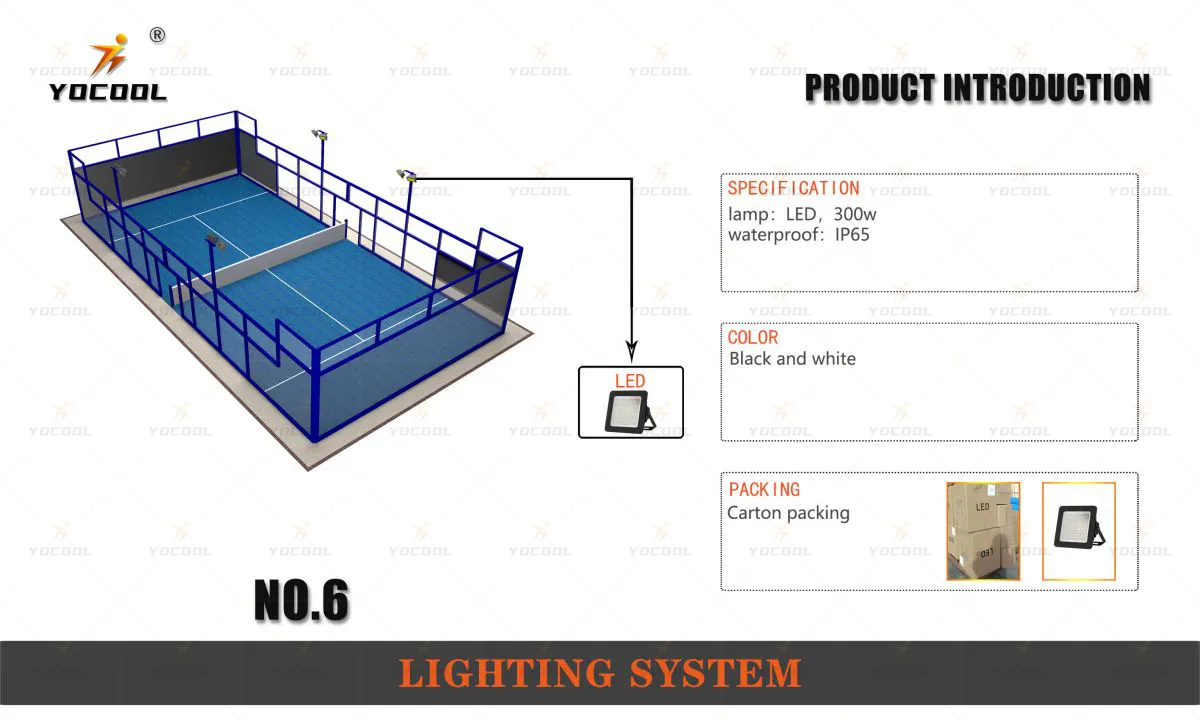

4. Assembly Once fabricated, the components are transported to the installation site. The assembly of the court is a meticulous process, requiring experienced installers to ensure that each part fits together seamlessly. This stage also includes the installation of lighting systems, spectator areas, and other facilities that enhance the court's functionality.

5. Quality Control and Testing Before a padel court is deemed ready for use, it undergoes rigorous quality control and testing. Each aspect of the court, from the surface texture to the structural integrity of the walls, is examined. This step ensures that the court will provide a safe and enjoyable experience for players.

Innovation in Padel Court Design

As the popularity of padel continues to rise, so does innovation in court design and manufacturing. Many factories are exploring eco-friendly materials and sustainable practices, creating courts that minimize environmental impact. Additionally, advancements in technology are leading to the development of smart courts equipped with sensors that track player performance and enable real-time feedback.

The Future of Padel Courts

The future of padel courts is bright, with an increasing number of facilities being built worldwide. As more people discover the joy of playing padel, the demand for high-quality courts is expected to rise significantly. Padel ball court factories play a pivotal role in this growth, continuously adapting and innovating to meet the needs of players and enthusiasts.

With governments and private investors recognizing padel’s potential as a community-building sport, more funding is being directed towards building dedicated padel complexes. This not only enhances accessibility but also promotes a healthy lifestyle among communities.

Conclusion

The manufacturing of padel ball courts is a fascinating mix of art, science, and sport. As the interest in padel continues to soar, so too does the complexity and sophistication of court production. The commitment of manufacturers to quality, innovation, and sustainability will undoubtedly shape the landscape of this dynamic sport for years to come. Whether you're a professional player or a beginner enjoying a weekend match, the growth and advancement of padel courts ensure that the game remains enjoyable and accessible to all.

Homogeneous Transparent Floor – Durable & Stylish Rubber Floor Solutions

Premium Homogeneous Transparent Floor for Durable & Stylish Spaces Rubber Floor Solutions

Premium Sports Floor Solutions Durable PVC Sports Floor & Rubber Floor for Gyms

Durable Rubber Composite Floor Premium Rubber Floor & Mats Solutions

Premium Rubber Composite Floor – Durable, Non-Slip, Eco-Friendly Rubber Floor Mats for Commercial & Residential Use

Premium Rubber Floor Solutions Rubber Floor Mat & Rubber Composite Floor for All Spaces