Paddle in Ping Pong Factories Revolutionizing Production Techniques

In the world of manufacturing, the term paddle often conjures images of craftsmanship and precision. In ping pong factories, paddles are not just tools of play, but also vital components of a booming industry that fuses technology with traditional craftsmanship. This article dives into the production techniques utilized in the manufacture of ping pong paddles, shedding light on how innovation is reshaping this niche field.

Paddle in Ping Pong Factories Revolutionizing Production Techniques

Once the wood is selected, the manufacturing process begins. Advanced machinery cuts and shapes the wood layers into the desired form, ensuring precision that manual labor may not achieve. However, many high-end paddles still incorporate hand-finishing techniques, reflecting the artistry involved in creating a top-notch product. Skilled artisans are responsible for crafting the paddle’s handle, which must provide a comfortable grip while allowing for agile maneuverability during play.

The next step is the application of rubber to the paddle’s surface. The type of rubber used can significantly influence gameplay. Factories have begun to experiment with various formulations of rubber, including different thicknesses and textures, to produce paddles suited for various playing styles—be it defensive, offensive, or all-round play. This level of customization means that players can select paddles tailored to their specific preferences, enhancing their overall experience and performance.

Quality control plays a pivotal role in the production process. Factories employ rigorous testing standards to ensure every paddle meets performance criteria. This involves checking for balance, weight distribution, and surface smoothness. The rise of technology has also enabled the use of automation in monitoring these standards, ensuring consistency across large batches of production.

As the ping pong industry continues to expand globally, particularly in Asia and Europe, factories are adapting to meet the growing demand. The integration of smart technology, such as IoT and AI, is starting to make waves in the manufacturing process, optimizing production efficiency and reducing waste. In addition, these technologies facilitate real-time monitoring of quality standards, further ensuring that consumers receive a product that meets their expectations.

In conclusion, the production of ping pong paddles is a fascinating blend of tradition and innovation. By harnessing advanced techniques while honoring artisanal craftsmanship, factories are not just making paddles—they are crafting experiences that resonate with players around the world. As this industry continues to evolve, the paddle remains a symbol of excellence and precision in the game of ping pong.

Premium Paddle Tennis Rackets for Every Court & Player

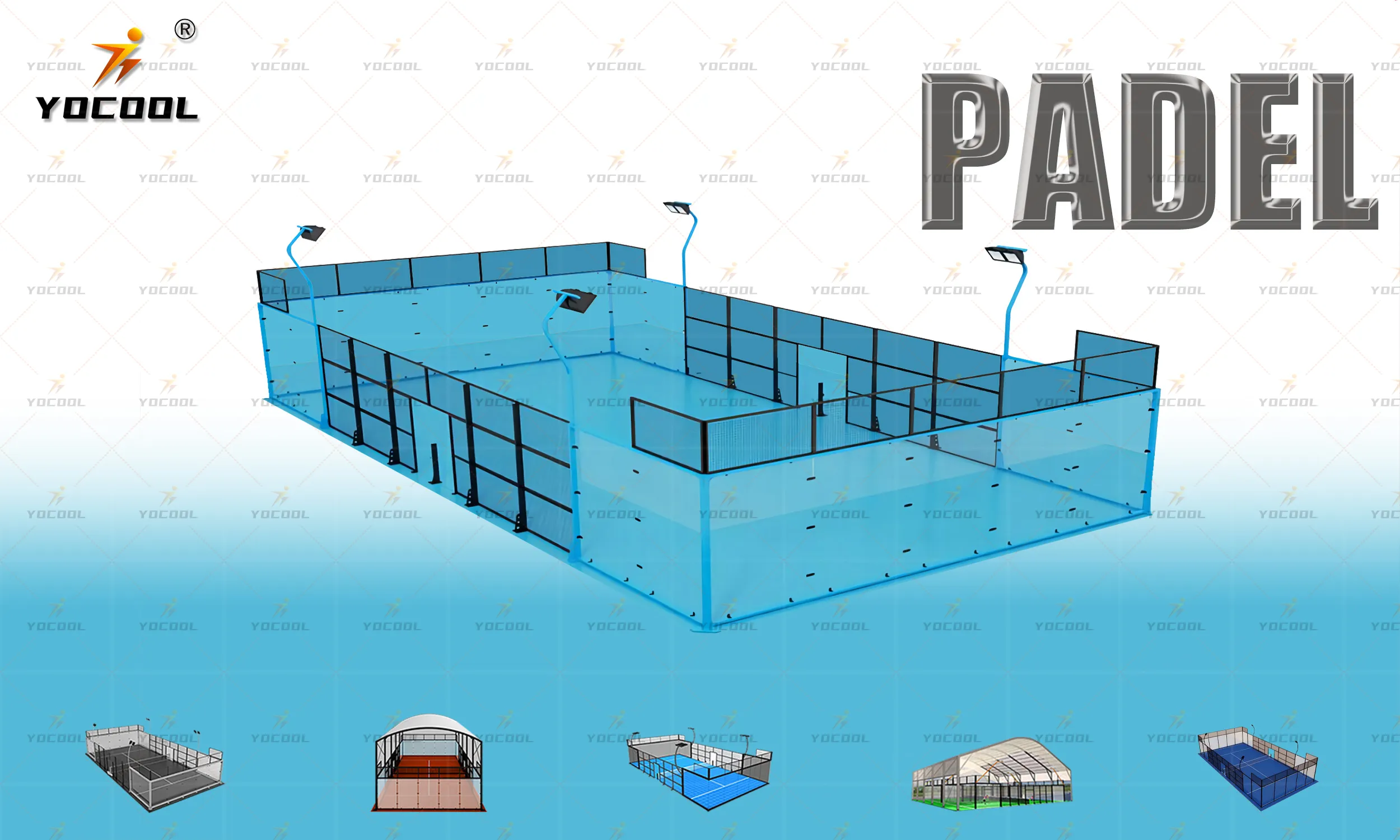

Premium Padel Courts: Expert Design & Installation Services

Premium Padel Courts: Panoramic Designs & Custom Builds

Premium Padel Court | Custom Designs & Quality Installation

Paddle Tennis Rackets: Unleash Power & Precision on Court

Best Paddle Tennis Rackets: Power, Control & Comfort