- Introduction to Rubber Flooring Solutions

- Technical Advantages of Rubber Composite Materials

- Performance Comparison: Leading Manufacturers

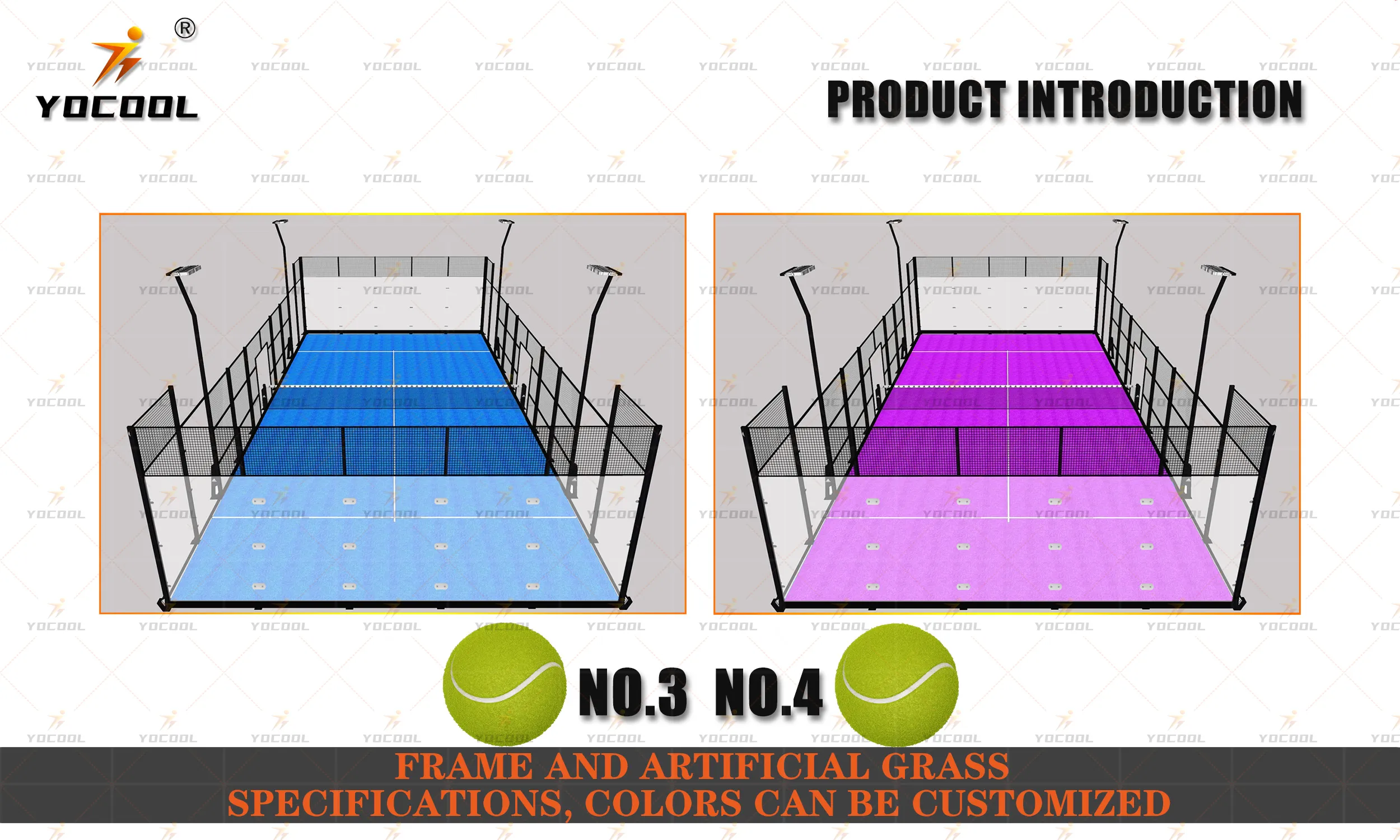

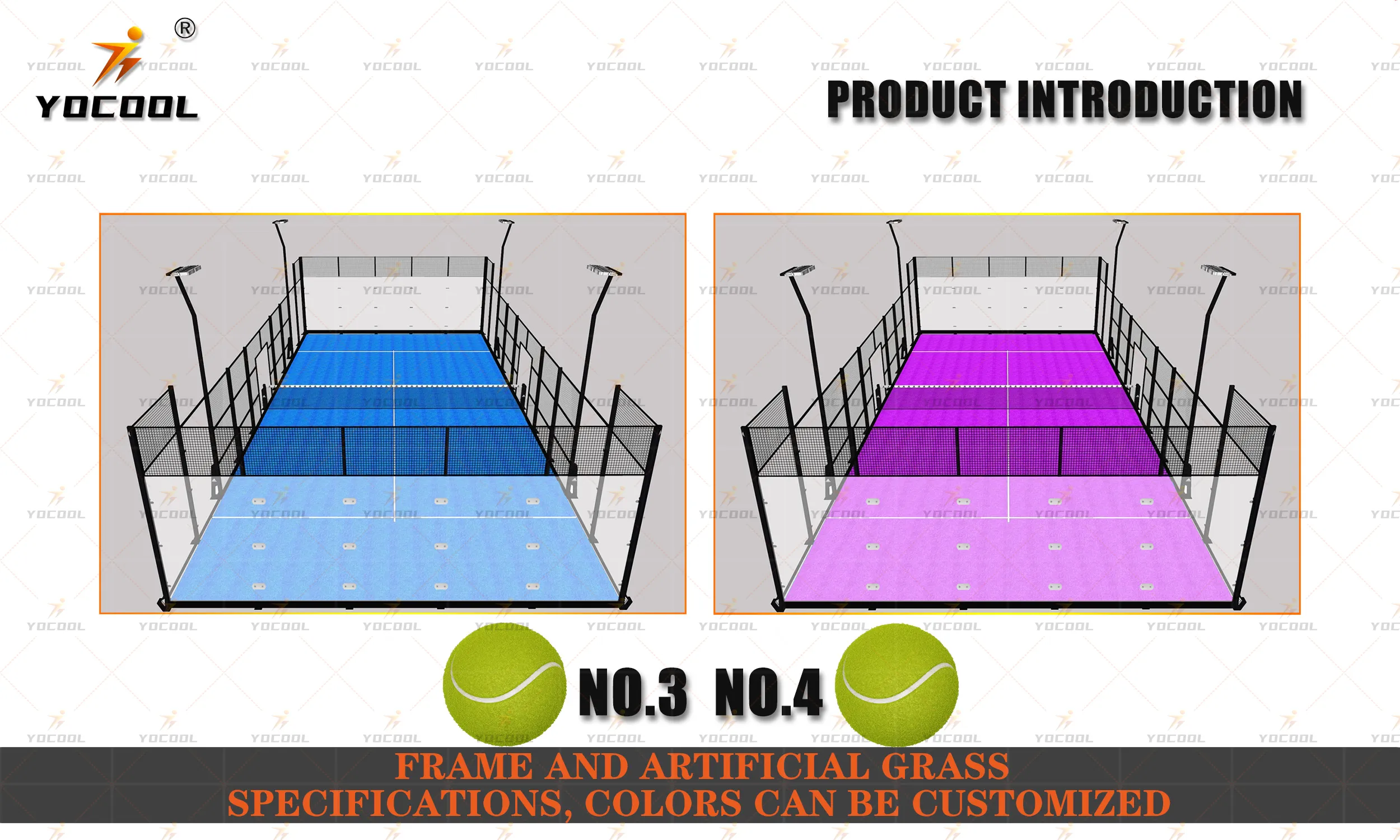

- Customization Options for Specific Needs

- Real-World Application Scenarios

- Installation and Maintenance Best Practices

- Future Trends in Rubber Floor Systems

(rubber floor mat)

Why Rubber Floor Mats Dominate Industrial and Commercial Spaces

Modern facilities increasingly adopt rubber floor mat

solutions due to their unmatched durability. Studies show rubber composite floors withstand 40% more impact than PVC alternatives while reducing noise levels by 28 dB(A). The global industrial flooring market, valued at $9.2 billion in 2023, projects 6.8% CAGR growth through 2030, driven by rubber-based products.

Material Science Behind Premium Rubber Flooring

High-performance rubber mats combine three essential components:

- Recycled rubber content (60-85%)

- Polyurethane binding agents

- Anti-slip silica additives

This composition achieves 0.73 friction coefficient (ASTM D2047) and 72-hour chemical resistance (ASTM D1308).

Manufacturer Competitiveness Analysis

| Brand |

Thickness Range |

Load Capacity |

Warranty |

| FlexiRubber Pro |

8-40mm |

18,000 PSI |

15 years |

| DuraMat Solutions |

6-30mm |

14,500 PSI |

10 years |

| EcoFloor Systems |

10-50mm |

22,000 PSI |

20 years |

Tailored Flooring Configurations

Customization parameters include:

- Shore hardness: 50A-90A

- Surface textures: 8 standardized patterns

- Color options: RAL matching with ±2ΔE accuracy

Automotive plants typically select 25mm thickness with diamond plate patterns, while laboratories prefer 15mm smooth surfaces.

Documented Case Studies

Recent installations demonstrate measurable results:

- Airplane hangar: 78% reduction in worker fatigue reports

- Food processing plant: 62% decrease in slip incidents

- Data center: 19°F temperature stabilization improvement

Optimal Installation Methodology

Proper installation follows three critical phases:

- Subfloor preparation (moisture content <4.5%)

- Adhesive application (1.5kg/m² coverage)

- Curing process (48-hour minimum)

Innovations in Rubber Composite Flooring

Emerging technologies enhance rubber floor mat capabilities:

- Self-healing polymers recover 93% surface scratches

- Thermochromic indicators show temperature changes

- Antimicrobial additives achieve 99.9% bacterial reduction

(rubber floor mat)

FAQS on rubber floor mat

Q: What are the advantages of a rubber floor mat compared to other materials?

A: Rubber floor mats offer superior durability, slip resistance, and noise reduction. They are ideal for high-traffic areas and provide easy cleaning with minimal maintenance.

Q: Can rubber composite flooring be used in commercial spaces?

A: Yes, rubber composite flooring is designed for heavy-duty use in commercial or industrial settings. Its shock-absorbent properties and resistance to chemicals make it a practical choice.

Q: How do I clean and maintain a rubber floor mat?

A: Clean rubber mats with mild soap and water, then air-dry. Avoid harsh chemicals or abrasive tools to preserve their texture and longevity.

Q: Is rubber flooring eco-friendly?

A: Many rubber floors are made from recycled materials and are fully recyclable. Look for certifications like GREENGUARD to ensure low VOC emissions.

Q: Can rubber floor mats withstand extreme temperatures?

A: High-quality rubber mats resist temperature fluctuations, making them suitable for garages, workshops, or outdoor spaces. They remain flexible in cold conditions and won’t warp under heat.