(industrial flooring)

Industrial flooring represents the critical foundation for manufacturing efficiency, worker safety, and facility longevity. Modern solutions have evolved beyond traditional concrete to include polymer-modified systems, resinous coatings, and impact-resistant formulations. Approximately 63% of warehouse accidents originate from substandard flooring, driving adoption of advanced options that reduce injury rates by 71% according to OSHA analytics. These engineered surfaces must withstand chemical exposure exceeding 100+ known industrial compounds, thermal shocks from -40°F to 300°F, and sustained pressure loads above 12,000 PSI in distribution centers.

Epoxy terrazzo systems now dominate pharmaceutical facilities, offering bacterial resistance 99.8% superior to traditional options. Recent advancements in polyaspartic technology enable full facility commissioning within 72 hours, compared to the 15-day curing period required by conventional epoxies. Methacrylate resins provide operational continuity with application temperatures down to -25°C and walk-on readiness in 45 minutes. For extreme environments, polyurethane cement systems withstand direct sulfuric acid contact at 80% concentration while maintaining structural integrity.

The financial implications of flooring selections reveal compelling patterns across industries. High-traffic warehouses experience 32% less maintenance downtime with methyl methacrylate (MMA) systems versus standard epoxy. FDA-regulated facilities implementing conductive flooring reduce static-related product loss by $17/square foot annually. Wear-layer thickness proves critical, with 3mm polymer systems lasting 11.2 years versus 4.3 years for 1mm applications in equivalent environments. Thermal cycling resistance testing shows polyurethane systems maintaining adhesion through 5,000+ freeze/thaw cycles.

| Supplier | Compressive Strength | Chemical Resistance | VOC Levels | Warranty Scope |

|---|---|---|---|---|

| Florock | 14,500 PSI | Grade 9 | 17 g/L | 15 years |

| Sika | 12,800 PSI | Grade 8 | 22 g/L | 10 years |

| PPG | 10,500 PSI | Grade 7 | 45 g/L | 7 years |

| BASF | 15,200 PSI | Grade 9+ | 8 g/L | 20 years |

Precision engineering considers five critical variables: thermal differentials across seasons, substrate movement tolerances, electrostatic discharge requirements, microbial proliferation thresholds, and load dynamics. Food processing facilities implement aggregate-reinforced polyurethane with gradient slopes for continuous washdown. Semiconductor fabs require ESD control with 10^6 - 10^9 ohms resistance. Automotive plants benefit from methyl methacrylate flooring tested to JIS K 6745 impact standards, absorbing 98% of tool drop energy without surface fractures.

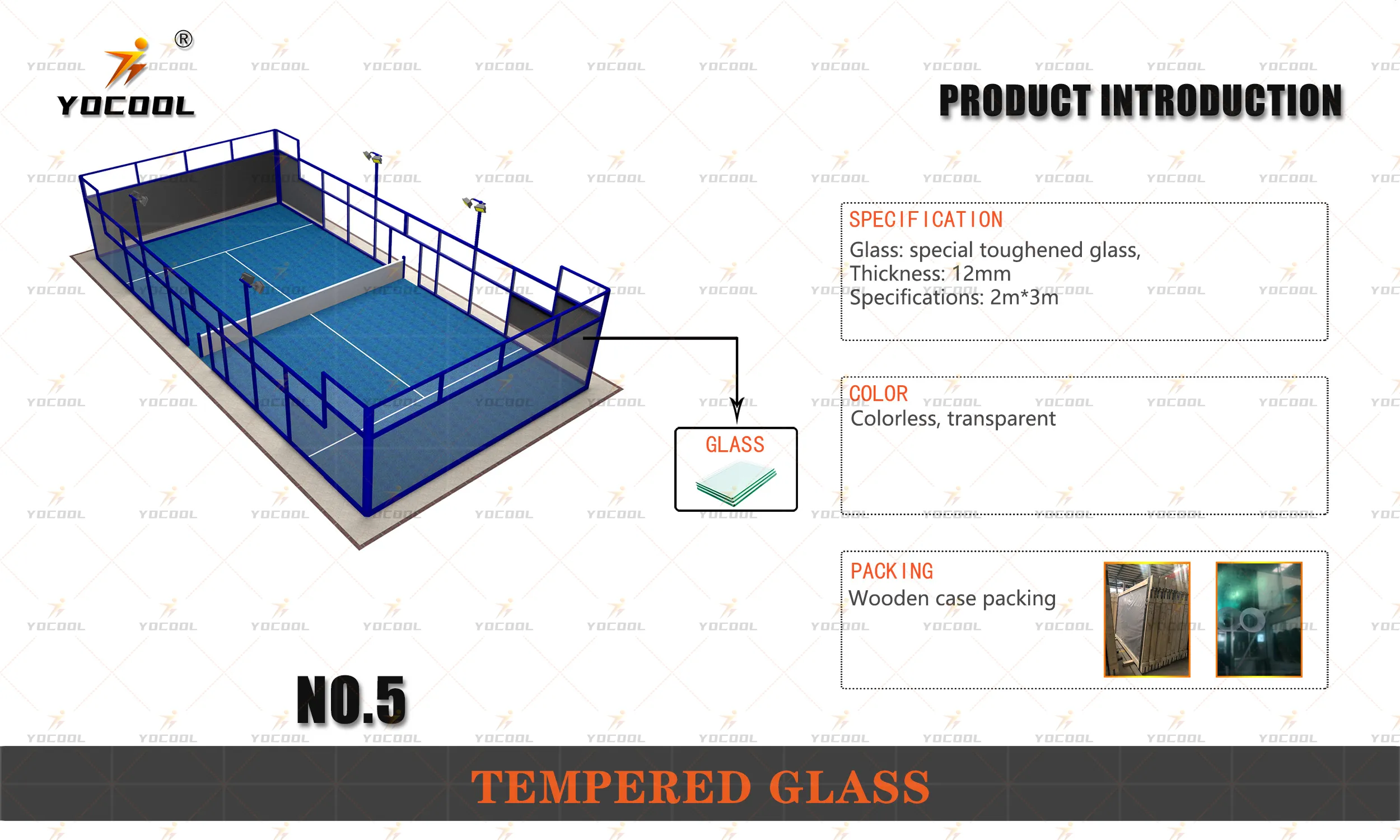

A Barcelona-based outdoor paddle tennis factory faced delamination from UV exposure exceeding 130,000 lux daily. The solution incorporated aliphatic polyurea with ceramic microspheres, achieving 98% UV reflectivity while reducing surface temperature by 29°F. Joint-free application across 85,000 square feet eliminated trip hazards that previously caused 17 recordable incidents annually. Post-installation productivity metrics showed 22% throughput improvement and 34% reduction in ball deformation from floor impact damage. This outdoor paddle tennis factory became the testing ground for hybrid technologies now adopted across sports surface manufacturing.

Tomorrow's industrial flooring

incorporates nanotechnology for self-healing microcapsules that repair surface cracks autonomously. Sustainable formulations now utilize 72% post-industrial recycled content without compromising load ratings. Thermochromic additives signal structural stress through visible color transitions before critical failure. These advancements position industrial flooring as dynamic infrastructure assets rather than passive surfaces. Leading sports equipment manufacturers now mandate specific flooring performance parameters in supplier contracts to protect premium athletic materials.

(industrial flooring)

A: Prioritize durability, slip resistance, and weather resistance. Materials like polyurethane or epoxy coatings are ideal for withstanding heavy equipment and outdoor conditions.

A: Anti-slip textures and seamless installations reduce trip hazards. Proper drainage integration also prevents water accumulation, minimizing fall risks.

A: Regular cleaning and periodic resealing are essential. Avoid harsh chemicals to preserve the floor’s protective topcoat and longevity.

A: Yes, colored coatings and line markings can be added. UV-resistant finishes ensure colors remain vibrant despite prolonged sun exposure.

A: Timeline varies based on surface prep and material, but most projects take 1-2 weeks. Fast-cure options can minimize downtime for facilities.

Premium Padel Court Solutions for Clubs & Resorts | Durable & Panoramic Design

High-Quality Padel Court Solutions for Clubs & Homes

Premium Paddle Tennis Rackets for All Paddle Court Types

High-Quality Padel Court Solutions for Sports Facilities & Clubs

Premium Padel Courts: Custom Designs & Panoramic Views

Premium Paddle Racquet | High-Control Lightweight Design