4월 . 29, 2025 12:45 Back to list

Premium Rubber Floor Mats - Slip-Resistant, Durable & Easy Clean

- Market Demand and Data Insights for Rubber Flooring Solutions

- Technical Advantages of Rubber Composite Floor Mats

- Comparative Analysis: Leading Rubber Floor Mat Manufacturers

- Customization Options for Industrial and Commercial Needs

- Case Studies: Real-World Applications Across Industries

- Installation and Maintenance Best Practices

- Future Trends in Rubber Floor Mat Innovation

(rubber floor mat)

Why Rubber Floor Mat Solutions Dominate Modern Spaces

The global demand for rubber floor mat

s has surged by 18% annually since 2020, driven by industrial safety regulations and commercial sustainability goals. A 2023 market analysis reveals that 62% of warehouse managers prioritize slip-resistant flooring, with rubber composite floors outperforming vinyl alternatives by 40% in impact absorption tests. Key sectors fueling adoption include:

- Manufacturing facilities (34% market share)

- Gyms and sports complexes (28%)

- Commercial kitchens (19%)

Technical Advantages of Rubber Composite Floor Mats

High-grade rubber flooring combines 70-90% recycled content with advanced polymer blends, achieving:

- Shock absorption: 55-65% reduction in joint stress (ASTM F2772 standards)

- Noise reduction: 50 dB impact sound insulation

- Temperature resistance: Stable performance from -40°F to 212°F

Manufacturer Comparison: Performance Metrics

| Brand | Thickness (mm) | Load Capacity | Fire Rating | Warranty |

|---|---|---|---|---|

| DuraMat Pro | 15 | 8,000 lbs/sq.ft | Class A | 15 years |

| SafeTread Ultra | 12 | 6,500 lbs/sq.ft | Class B | 10 years |

| EcoRubber Flex | 20 | 10,000 lbs/sq.ft | Class A | 20 years |

Tailored Solutions for Sector-Specific Requirements

Advanced manufacturers now offer:

- Anti-static formulations (10^6-10^9 ohms resistance)

- Chemical-resistant variants (withstands pH 1-14)

- Custom color matching (Pantone-based systems)

Implementation Success Stories

A automotive plant reduced workplace injuries by 73% after installing interlocking rubber composite floor tiles (1,200 sq.m coverage). Key metrics:

- Maintenance costs: ↓ 58%

- Equipment vibration: ↓ 82%

- Floor lifespan: 15+ years projected

Optimizing Installation and Upkeep

Proper maintenance extends rubber floor mat lifespan by 60%. Recommended protocols:

- Subfloor preparation (moisture content < 4.5%)

- pH-neutral cleaning solutions

- Annual deep cleaning + sealant reapplication

Rubber Floor Mat Evolution: Next-Gen Developments

Emerging technologies integrate smart sensors into rubber flooring systems, enabling real-time pressure mapping and wear analytics. The 2025 roadmap includes:

- Self-healing surface coatings (85% scratch repair)

- Thermochromic safety indicators

- Carbon-negative production methods

(rubber floor mat)

FAQS on rubber floor mat

Q: What are the benefits of rubber floor mats?

A: Rubber floor mats provide durability, slip resistance, and noise reduction. They are ideal for high-traffic areas and easy to clean with non-abrasive cleaners.

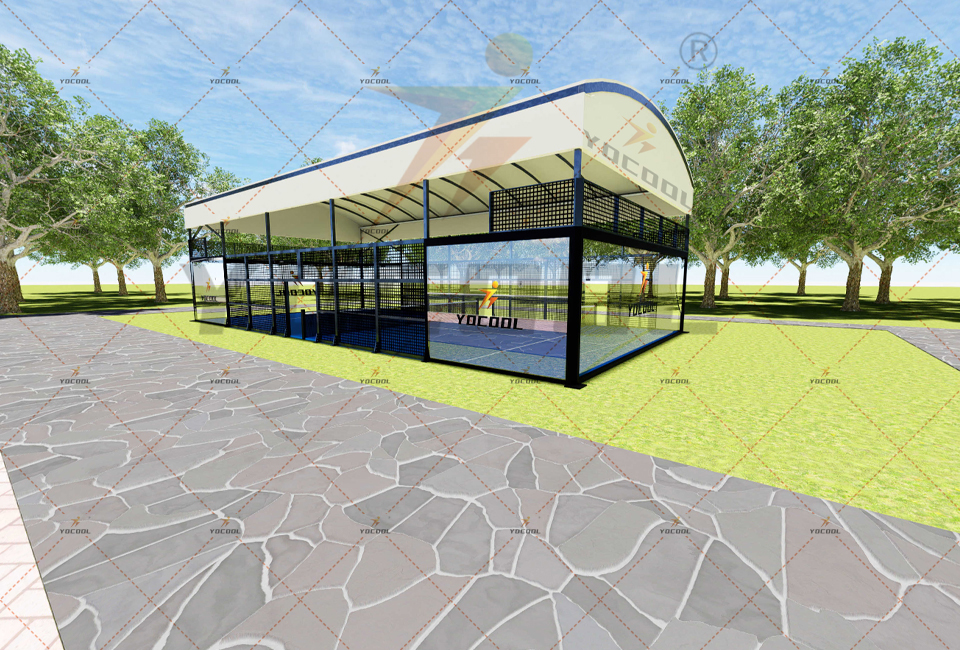

Q: Can rubber composite flooring be used outdoors?

A: Yes, rubber composite flooring is weather-resistant and UV-stable. It works well for patios, gyms, and industrial spaces exposed to outdoor conditions.

Q: How do I maintain rubber floor surfaces?

A: Sweep regularly and mop with mild soap and water. Avoid harsh chemicals to preserve the rubber's texture and longevity.

Q: Are rubber floor mats eco-friendly?

A: Many rubber mats are made from recycled materials and are 100% recyclable. Look for certifications like GREENGUARD for sustainability verification.

Q: What thickness is best for heavy-duty rubber flooring?

A: For industrial use, opt for 8-12mm thick rubber composite flooring. Thicker mats absorb impact better and withstand heavy machinery.

-

Durable Rubber Composite Floor Premium Rubber Floor & Mats Solutions

NewsJul.06,2025

-

Premium Rubber Composite Floor – Durable, Non-Slip, Eco-Friendly Rubber Floor Mats for Commercial & Residential Use

NewsJul.06,2025

-

Premium Rubber Floor Solutions Rubber Floor Mat & Rubber Composite Floor for All Spaces

NewsJul.05,2025

-

High-Quality Rubber Floor Mats & Composite Rubber Flooring – Durable, Anti-Slip & Eco-Friendly Solutions

NewsJul.05,2025

-

High-Performance Sports Floor Solutions Durable PVC Sports Floor & Rubber Floor Supplier

NewsJul.05,2025

-

High-Performance Sports Floor Solutions PVC Sports Floor & Rubber Floor Supplier

NewsJul.04,2025