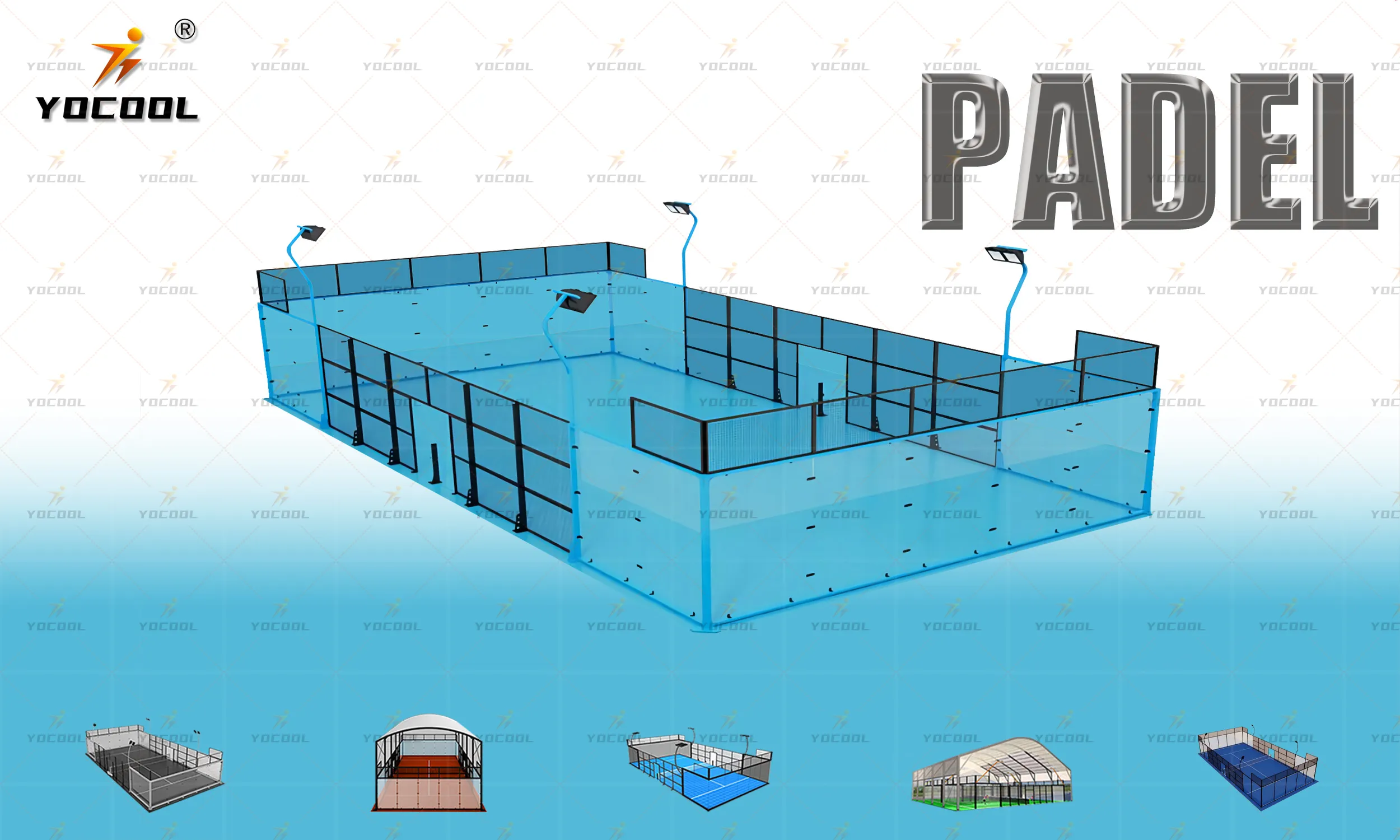

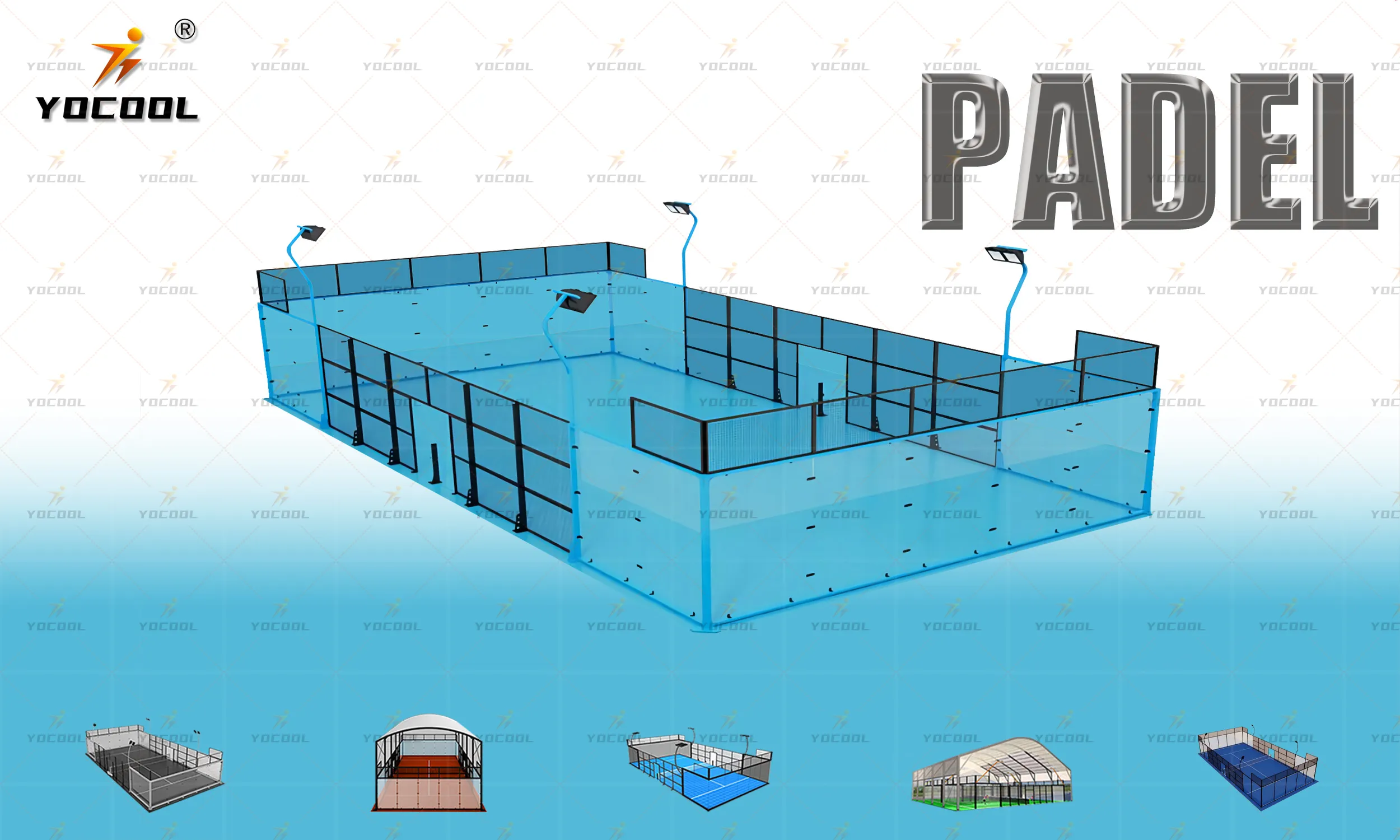

In the dynamic world of racquet sports equipment, the forefront of innovation is an intriguing blend of tennis, squash, and padel rackets. Navigating this triumvirate of sports gear requires not only a keen understanding of sports biomechanics but also a commitment to cutting-edge manufacturing techniques. Leading the charge in creating high-performance equipment are manufacturers that fuse both tradition and technology to craft products designed for athletes who demand excellence. Their expertise and authority in the industry are built on decades of experience, pushing boundaries to meet and exceed user expectations.

Producing top-tier tennis rackets, squash rackets, and padel rackets involves a meticulous process beginning with material selection. Advanced composite materials such as carbon fiber, fiberglass, and Kevlar are preferred for their unique properties of strength, flexibility, and lightweight performance. Expertise in material science allows manufacturers to tailor these properties, enhancing the racket's specifications, such as swing weight, balance, and durability. By leveraging these innovations, manufacturers ensure that each piece of equipment not only meets the international standards of competitive play but also amplifies the player's natural abilities.

The design and engineering phases play a crucial role in the performance of racquets. Using state-of-the-art CAD software, engineers craft detailed blueprints that address specific player needs, whether it's delivering more power, control, or spin. Leading manufacturers employ iterative prototyping, actively engaging in rigorous testing and seeking feedback from professional athletes. This approach ensures that the final products resonate with the demands of contemporary gameplay and are built on a foundation of engineered excellence.

Furthermore, the manufacturing process itself is a testament to authoritative control over quality and output. Advanced robotic assembly and precision machining techniques are employed to ensure consistent performance across every unit produced. Alongside automated processes, there still exists skilled craftsmanship; seasoned artisans imparting refined techniques that machines cannot replicate, such as intricate handle wrapping or specific tension adjustments in strings. This blend of automation and craftsmanship results in racquets that players can trust for reliability and peak performance.

tennis squash padel manufacturer

Trustworthiness in this sphere is underscored by transparent business practices and sustainable operations. Leading manufacturers openly commit to environmental stewardship, implementing eco-friendly practices in material procurement and production processes. They engage in ethical labor practices, ensuring safe and fair working conditions across all tiers of their supply chain. By fostering a reputation for integrity, these manufacturers not only enhance trustworthiness but also build a legacy centered on responsible innovation.

Endorsements from globally recognized athletes further cement a manufacturer's authority. By becoming the equipment of choice for top players, the manufacturer's products gain credibility and recognition as leaders in the industry. This partnership is further amplified by the manufacturers' participation in international sports expos and partnerships with sports associations, where they showcase breakthroughs in technology and design to a global audience.

In conclusion, the manufacturing of tennis, squash, and padel equipment is an exercise in unyielding dedication to progress and quality. By harnessing the power of innovation, material science, expert engineering, and ethical practices, these manufacturers set a benchmark in the industry. Their influence extends beyond products to inspire confidence, enhance performance, and shape the future of racquet sports.