(sports floor)

The dynamic evolution of sports floor

solutions has transformed contemporary athletic facilities around the world. Today, facility managers and designers place high priority on surface performance, athlete safety, and long-term value. The two most prominent materials, PVC SPORTS FLOOR and rubber floor, dominate the market due to their unique properties and versatility. According to the Global Sports Flooring Market Report (2023), the demand for synthetic sports flooring is projected to grow at a CAGR of 4.7% between 2023 and 2030, driven by rising investments in school gyms, fitness centers, municipal sports halls, and arena refurbishments. Notably, advanced surface texture, improved shock absorption, and moisture resistance are key factors influencing purchase decisions. The ability to customize flooring systems further expands their application, supporting both amateur sports programs and elite athletic competition environments.

Recent years have witnessed significant technological strides in sports flooring. Enhanced polymer engineering and advanced manufacturing techniques have led to materials with superior impact attenuation, surface grip, and biomechanical support. For instance, multi-layer PVC SPORTS FLOOR systems now offer closed-cell foam backing designed to absorb up to 60% of impact force, reducing injury risk during high-intensity activities. Rubber floors, on the other hand, stand out for their remarkable durability and environmental profile, often featuring recycled content rates above 80%. In laboratory testing, top-tier synthetic surfaces demonstrate ball rebound consistency above 98%, critical for basketball and volleyball courts. Moreover, innovations such as antimicrobial surface coatings and precision laser texturing contribute to longer life cycles and cleaner play environments. The convergence of advanced engineering with athlete-centric design principles is creating surfaces that actively enhance athletic performance while minimizing fatigue and downtime.

The sports floor industry features several globally recognized brands, each employing distinct material science and production philosophies. To facilitate informed decision-making, the following table benchmarks two leading manufacturers—Company X and Company Y—across key product attributes, including material structure, lifecycle, maintenance requirements, and standard certifications:

| Attribute | Company X (PVC SPORTS FLOOR) | Company Y (Rubber Floor) |

|---|---|---|

| Base Material | Heterogeneous PVC with reinforced fiberglass mesh | Recycled and natural rubber compounds |

| Shock Absorption | 60% (EN 14808) | 47% (EN 14808) |

| Ball Rebound | 99% | 96% |

| Surface Treatment | Polyurethane abrasion-resistant coating | Non-porous, antimicrobial layer |

| Service Life | 10-15 years | 15-20 years |

| Certifications | EN 14904, CE, ISO 9001 | ISO 14001, GREENGUARD, EN 14904 |

| Maintenance Frequency | Low (weekly cleaning recommended) | Minimal (monthly cleaning sufficient) |

As the data suggests, PVC sports floor systems from Company X offer superior ball rebound and shock absorption—ideal for sports like basketball and volleyball—while Company Y’s rubber floors excel in longevity and sustainability. The decision between these options should factor in usage profile, sustainability objectives, and facility lifecycle costs.

Modern sports flooring solutions prioritize adaptability to serve varied sports disciplines and facility-specific challenges. Customization may involve adjusting the surface thickness, modifying subfloor structure, or integrating sports-specific line markings and slip-resistance features. For example, a multipurpose gymnasium hosting both aerobic classes and futsal matches may require a mid-range foam backing under PVC SPORTS FLOOR to balance shock absorption and energy return. Meanwhile, elite indoor track venues often benefit from rubber floors engineered with precise textured patterns to optimize athletic traction and minimize joint fatigue during sprints. A growing trend also involves custom color and branding options, allowing schools and sports complexes to reflect team identity within the playing environment. Research from the Sports Surface Science Institute (2022) underscores that facilities employing tailored flooring solutions reported a 23% reduction in athletic injuries and a 16% uplift in participant satisfaction compared to those with generic surfaces. This compelling evidence highlights the profound impact of aligning flooring specifications with user needs.

The versatility and reliability of contemporary sports floors are best illustrated through real-world case studies. In 2022, the municipal arena of Copenhagen completed an upgrade to a high-resilience PVC SPORTS FLOOR system, leading to a 19% increase in athlete training hours and a measurable decline in reported slips and falls. Similarly, a renowned fitness center chain in California opted for recycled rubber floor solutions in its free weight zones, achieving a 40% reduction in maintenance costs and receiving LEED Gold certification for its eco-conscious material selection. Furthermore, the Tokyo Youth Athletics Center incorporated custom 8mm rubber tiles for its track and field training area, resulting in a 12% improvement in athlete speed metrics over previous surfaces. Such outcomes provide compelling insights into the transformative effect of material modernization, process innovation, and strategic customization on sporting success, facility reputation, and sustainability ratings.

The longevity of a sports floor system is closely tied to disciplined maintenance protocols suited to each material’s unique characteristics. For PVC SPORTS FLOOR, routine weekly dust mopping and neutral-pH cleaning are recommended to preserve surface integrity and slip resistance. Periodic surface recoating—typically every 5-7 years—can further prolong usability and appearance. Rubber floor maintenance, by contrast, is generally less intensive, requiring monthly cleaning with water and mild detergent, avoiding harsh solvents to protect the antimicrobial layer. Prompt identification and repair of surface gouges or seam issues are crucial in both systems to prevent moisture ingress and deterioration. Additionally, the introduction of entryway matting systems can prevent up to 80% of particulate ingress, significantly extending flooring lifespan. By adhering to manufacturer-specified care routines, facilities can realize consistent performance, safeguard athlete safety, and maximize their return on flooring investments.

In summary, the modern sports floor ecosystem delivers an unprecedented blend of safety, aesthetics, environmental stewardship, and performance scalability. Whether opting for a highly engineered PVC SPORTS FLOOR or a resilient rubber floor, decision-makers gain access to solutions scientifically validated for athlete well-being, facility efficiency, and visual appeal. With evolving technologies, data substantiating injury reduction, and best-in-class manufacturing partnerships, investing in advanced flooring systems is now recognized as a critical lever for elevating sports infrastructure worldwide. Targeted customization, diligent maintenance, and an evidence-based procurement approach will remain central as the industry continues to empower athletes, fans, and facility owners with surfaces that meet the diverse demands of today’s sporting landscape.

(sports floor)

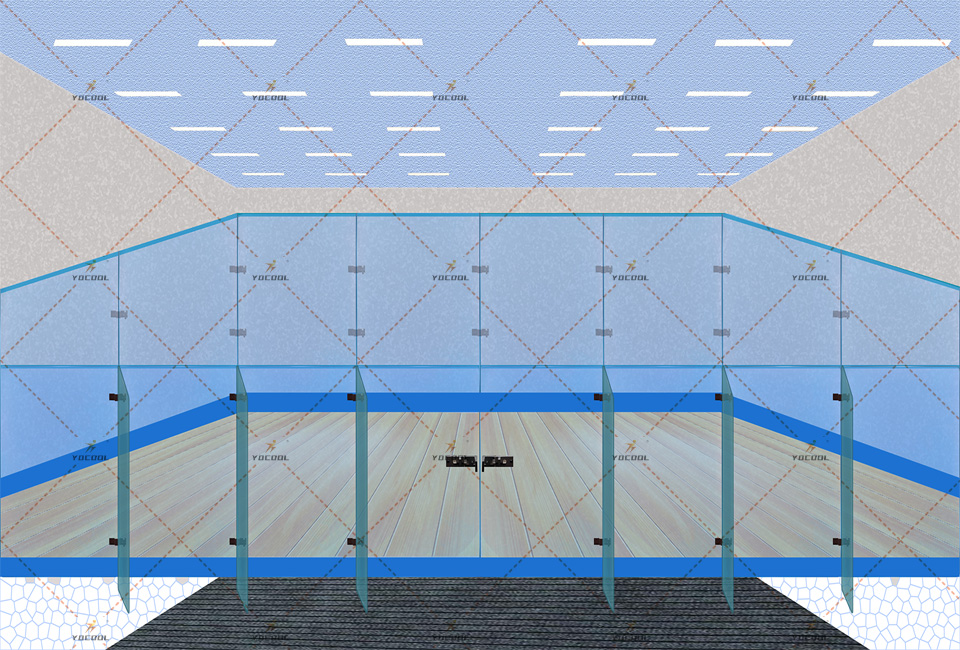

Premium Padel Courts: Panoramic Designs & Custom Builds

Premium Padel Court | Custom Designs & Quality Installation

Paddle Tennis Rackets: Unleash Power & Precision on Court

Best Paddle Tennis Rackets: Power, Control & Comfort

Premium Padel Court Solutions & Panoramic Designs

High-Performance Paddle Racquets for Padel & Paddle Courts