The Evolution of Racquetball and Tennis A Journey Through Factories

Racquetball and tennis, two popular racquet sports, have captured the hearts of millions around the world. While they may share certain similarities, each sport has a unique history and development that is deeply intertwined with the evolution of the equipment used. Central to this evolution are the factories that manufacture the racquets, balls, and other essential gear needed for these games. Understanding the contributions of these factories provides insight into how racquetball and tennis have transformed over the years.

Historical Background of Racquet Sports

Tennis, with roots tracing back to the late 12th century, initially started as a handball game in France. The game evolved significantly through the centuries, transitioning from palm to racquet and gaining popularity across Europe, particularly in the 19th century with the establishment of lawn tennis. The advent of factories during the Industrial Revolution was pivotal in producing tennis equipment on a larger scale, making the sport more accessible to the masses.

Racquetball, on the other hand, is a comparatively modern creation. Invented in the 1950s in the United States by Joe Sobek, it was designed to be played indoors with a focus on fast-paced gameplay. The sport gained traction quickly, and it wasn't long before dedicated factories emerged to create specialized racquets and balls tailored for racquetball enthusiasts.

The Role of Factories in Equipment Development

Factories play an essential role in shaping the quality and availability of sporting equipment. In the world of tennis, manufacturers like Wilson, Head, and Babolat have set the bar high with their commitment to innovation and technology. Early tennis racquets were predominantly made of wood, but advancements in factory techniques introduced materials like aluminum and, eventually, graphite. These materials allow for lighter, more durable racquets, enhancing player performance. Factories constantly push the envelope in technology; for instance, the introduction of moisture-wicking strings and vibration dampeners has revolutionized how players experience the game.

Racquetball factories have similarly embraced innovation. The racquets designed for racquetball games must withstand the intense impact of a solid rubber ball, which places unique demands on materials and construction. As a result, manufacturers like Ektelon and Head have introduced lightweight composite materials that enhance both strength and maneuverability. The factories dedicated to racquetball often tailor their production processes to respond to the sport's rapidly changing dynamics, adapting to trends such as new playing styles and player preferences.

Globalization and Outsourcing in Manufacturing

In recent decades, globalization has significantly influenced the manufacturing landscape of both tennis and racquetball equipment. Many well-known brands have shifted their production to countries with lower labor costs, such as China and Indonesia. While this has made equipment more affordable for consumers, it has raised concerns about quality control and ethical labor practices. Factories now navigate the balance between cost-effectiveness and maintaining high standards, which is vital for sustaining brand reputation in a competitive market.

Moreover, advances in technology allow for more efficient production methods. Factories are increasingly utilizing automation and robotics to streamline assembly processes. This technological shift increases output while minimizing human error, resulting in enhanced product quality. However, it also presents challenges in terms of maintaining skilled labor forces, as the demand for craftsmanship decreases in favor of mass production.

The Future of Racquet Sports Manufacturing

Looking ahead, the future of racquetball and tennis manufacturing is undoubtedly intertwined with technological advancements and consumer preferences. Eco-friendly materials and sustainable production practices are poised to play a significant role. Industry leaders are becoming increasingly aware of their environmental impact, prompting factories to explore options such as biodegradable materials and sustainable sourcing.

Additionally, the rise of personalized equipment is reshaping the landscape. Custom racquets tailored to individual player specifications are becoming more common, and factories are adapting their processes to accommodate this trend. As players seek to improve their performance through personalized gear, factories will play a crucial role in meeting these demands.

Conclusion

The factories behind racquetball and tennis equipment have witnessed remarkable transformations that mirror the evolution of the sports themselves. From the handcrafted wooden racquets of the past to the modern, technologically advanced gear of today, the journey has been both extensive and fascinating. As we move forward, it will be exciting to see how these factories continue to innovate, ensuring both sports thrive in an ever-changing world. Whether in a local court or a prestigious tournament, the impact of these factories resonates, allowing players to enjoy the games they love.

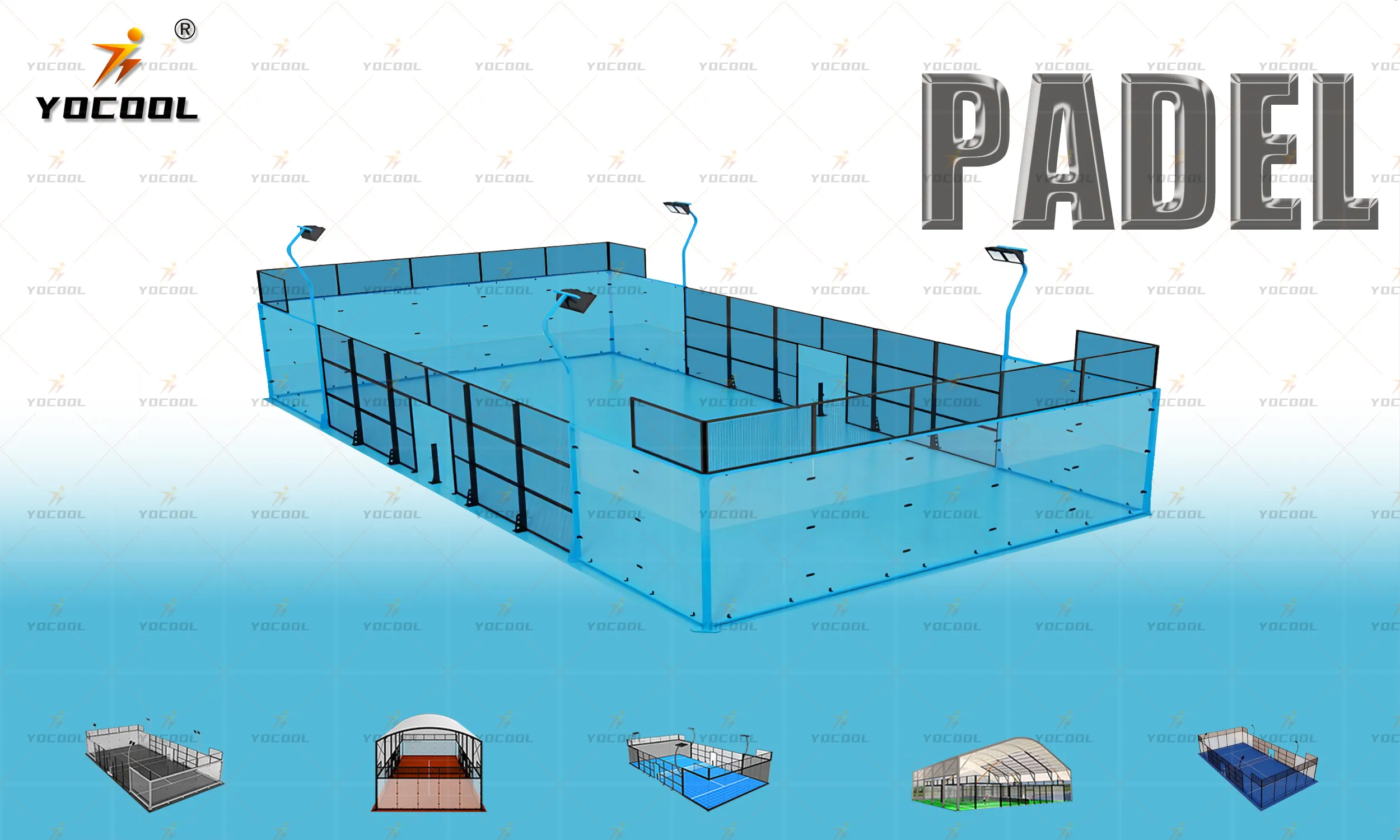

High-Quality Padel Court Solutions for Clubs & Homes

Premium Paddle Tennis Rackets for All Paddle Court Types

High-Quality Padel Court Solutions for Sports Facilities & Clubs

Premium Padel Courts: Custom Designs & Panoramic Views

Premium Paddle Racquet | High-Control Lightweight Design

NO.2 Panoramic Padel Orange Racket - Superior Grip & Durability