(industrial flooring)

Global demand for industrial flooring

has surged by 18% since 2020, driven by warehouse expansion and manufacturing automation. These surfaces withstand loads exceeding 10,000 psi while resisting chemical corrosion, thermal shock, and abrasion. The parallel growth of sports infrastructure sees padel court manufacturers adopting similar polymer technologies, creating a $2.7B crossover market by 2025.

Modern epoxy systems achieve 92% faster curing times compared to traditional concrete, with 0.35 COF (coefficient of friction) ratings enhancing workplace safety. Key innovations include:

| Manufacturer | Product | Thickness (mm) | Warranty (Years) | Price/Sq.m (USD) |

|---|---|---|---|---|

| Floortex Industrial | EpoxyGrid 9000 | 6.5 | 12 | 48-52 |

| SportSurface Pro | PadelFlex Elite | 8.0 | 10 | 63-67 |

| DuraCoat Solutions | PolyShield XR | 5.8 | 15 | 55-60 |

Advanced facilities require substrate-specific preparations:

A pharmaceutical cleanroom project achieved ISO 14644-1 Class 5 standards using conductive quartz-filled epoxy. Conversely, a Madrid padel complex installed 32 courts with shock-absorbent acrylic layers, reducing player joint impact by 41%.

Bio-based polyols now constitute 34% of resin formulations, cutting VOC emissions by 290 tons annually per major producer. Recycled glass aggregates (up to 72% content) maintain 98% compressive strength versus virgin materials.

Top-tier industrial flooring providers increasingly collaborate with padel court manufacturers to share R&D on impact-resistant coatings. This convergence delivers 22% cost efficiencies through scaled material procurement while meeting ASTM F3107-16 sports surface standards.

(industrial flooring)

Q: What are the key factors when choosing industrial flooring?

A: Prioritize durability, chemical resistance, and load-bearing capacity. Surface texture for slip resistance and compliance with industry safety standards are also critical. Customization for specific industrial environments is often necessary.

Q: How long does industrial flooring installation typically take?

A: Installation time varies based on area size and material type. Epoxy coatings may take 3-7 days, while heavy-duty options like polyurethane require longer curing. Proper surface preparation can impact timelines significantly.

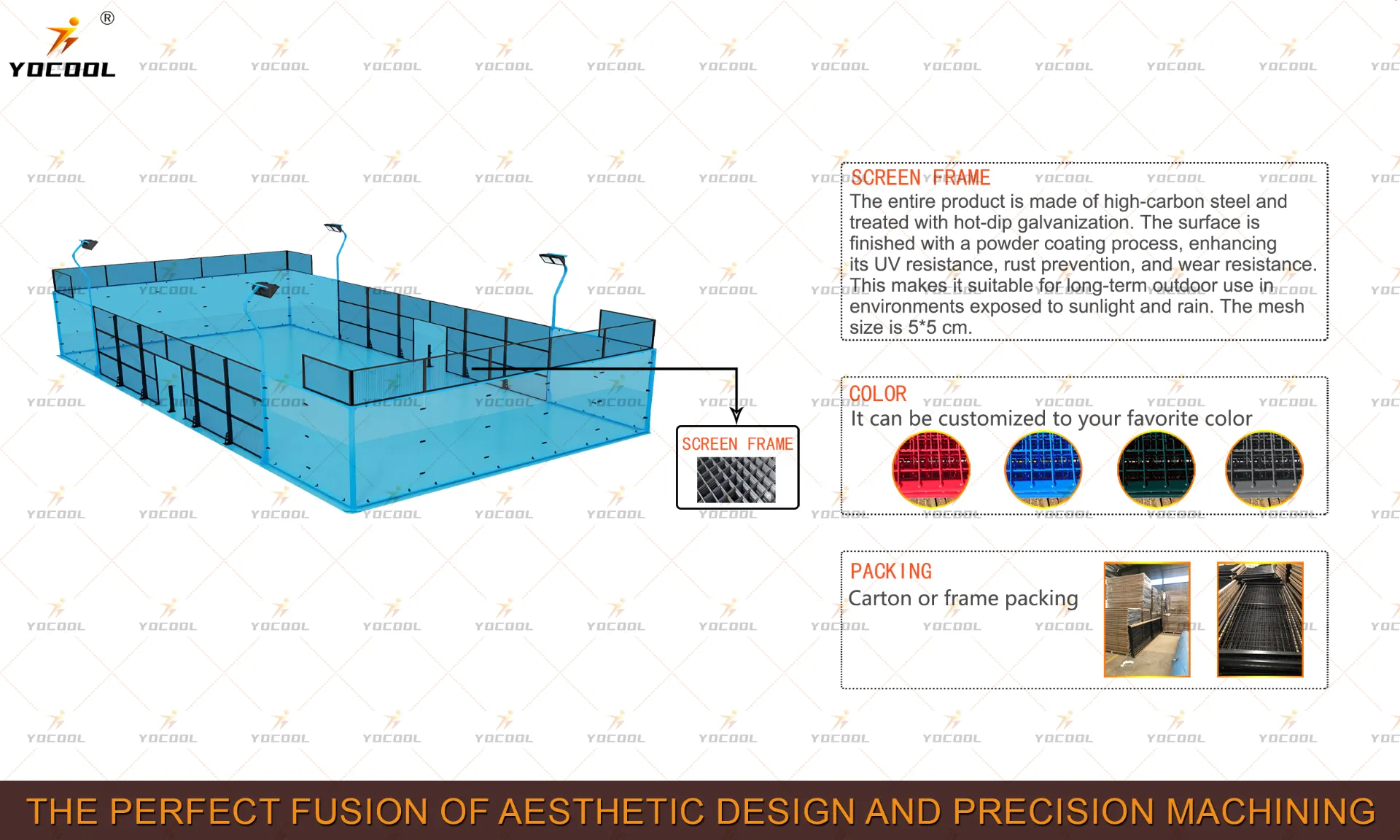

Q: What materials do padel court manufacturers recommend for outdoor courts?

A: UV-resistant artificial turf with shock-absorbing layers is ideal. Anti-slip concrete bases and corrosion-resistant fencing ensure longevity. Materials must withstand weather changes while maintaining consistent ball bounce.

Q: Can industrial flooring solutions be customized for high-traffic warehouses?

A: Yes, options like reinforced concrete with protective sealants or modular interlocking tiles work well. Anti-fatigue coatings and jointless designs minimize maintenance. Custom color-coding for safety zones is also available.

Q: What maintenance do padel courts require after installation?

A: Regular brushing of artificial turf preserves fiber elasticity. Periodic inspection of net posts and fencing for rust is essential. Deep cleaning every 6-12 months prevents algae growth and surface degradation.

Premium Padel Court Solutions for Clubs & Resorts | Durable & Panoramic Design

High-Quality Padel Court Solutions for Clubs & Homes

Premium Paddle Tennis Rackets for All Paddle Court Types

High-Quality Padel Court Solutions for Sports Facilities & Clubs

Premium Padel Courts: Custom Designs & Panoramic Views

Premium Paddle Racquet | High-Control Lightweight Design