(industrial flooring)

Global spending on industrial flooring

surpassed $12.8 billion in 2023, driven by a 6.7% CAGR since 2020. Warehouses account for 42% of installations, followed by manufacturing plants (33%) and sports facilities like padel courts (15%). The market shift toward chemical-resistant polyurethane systems (58% adoption rate) reflects increasing emphasis on workplace safety and operational efficiency.

Modern epoxy-polyurethane hybrid systems demonstrate 87% better impact resistance than traditional concrete, with 0.23% abrasion loss after 10,000 cycles (ASTM D4060). Key advancements include:

| Manufacturer | Material Tech | Installation Speed | Price/m² (USD) | Warranty |

|---|---|---|---|---|

| Floortex Pro | Polyaspartic | 400m²/day | $48-$52 | 20 years |

| Duraseal Industrial | Epoxy Hybrid | 350m²/day | $42-$47 | 15 years |

| PadelGuard Specialists | Acrylic Resin | 500m²/day | $55-$60 | 25 years |

Leading padel court cover manufacturers now integrate shock-absorbent layers (8-12mm thickness) that reduce player fatigue by 31%. Industrial facilities increasingly specify:

A German automotive plant reported 19% productivity gains after replacing worn concrete with methyl methacrylate (MMA) flooring. Key metrics:

Self-healing polymers capable of repairing 500μm cracks autonomously will enter commercial testing in 2025. Graphene-enhanced composites show potential for 3x thermal conductivity improvements, while photocatalytic titanium dioxide additives enable 82% NOx reduction in industrial atmospheres.

Facilities using advanced industrial flooring systems report 23% lower total ownership costs over 10 years compared to conventional options. The 2024 Global Facility Report confirms 91% of maintenance managers prioritize floor quality when upgrading plants, recognizing its critical role in operational safety and throughput optimization.

(industrial flooring)

Q: What materials are most durable for industrial flooring?

A: Epoxy resin, polyurethane, and concrete are top choices for industrial flooring due to their durability, chemical resistance, and ability to withstand heavy machinery. Material selection depends on traffic type and environmental conditions.

Q: What factors matter when selecting an industrial flooring contractor?

A: Prioritize contractors with industry-specific experience, certifications, and proven project portfolios. Ensure they use high-quality materials and comply with safety standards for long-lasting results.

Q: How to maintain industrial flooring for longevity?

A: Regular cleaning, immediate spill removal, and periodic resealing prevent wear. Avoid abrasive tools and use pH-neutral cleaners to preserve surface integrity.

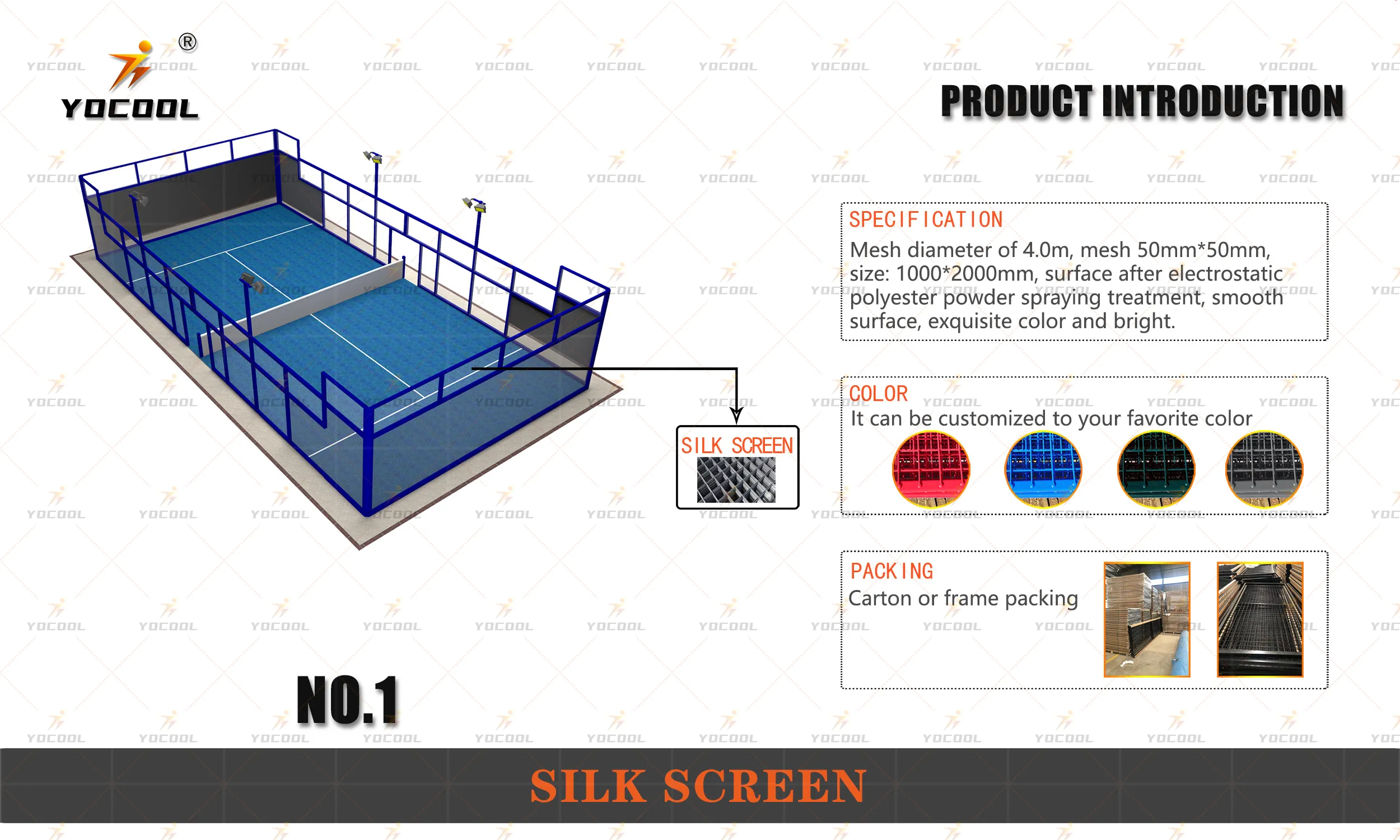

Q: What should I look for in padel court cover manufacturers?

A: Opt for manufacturers using UV-resistant, weatherproof materials like polyethylene. Ensure they offer custom sizing, anti-slip surfaces, and warranties for outdoor durability.

Q: Can padel court covers withstand outdoor conditions?

A: Yes, high-quality covers made from reinforced PVC or polyethylene resist rain, UV rays, and temperature shifts. Proper anchoring systems ensure stability in harsh weather.

Premium Rubber Composite Floor for Ultimate Durability & Safety Rubber Floor Mat Solutions

High-Quality Industrial Flooring Solutions for Factories Expert Installation & Cost Saving

Premium Rubber Brick Flooring Durable & Slip-Resistant

Durable & Non-Slip Rubber Flooring for Gym, Garage, Home

Durable Industrial Flooring Solutions China Padel Install

Durable Rubber Floor Slip-Resistant & Easy Clean