This comprehensive guide explores rubber floor

ing solutions for commercial and industrial applications. Key sections include:

(rubber floor)

Industrial facilities face unique flooring challenges requiring specialized solutions. Rubber flooring systems provide exceptional durability, with premium installations maintaining structural integrity for 15-25 years even under heavy machinery. Rubber composite floor materials recover completely from compression forces, maintaining their original thickness. Manufacturing facilities experience 30% fewer slip incidents after rubber installation according to OSHA data. The resilience quotient (measured by ASTM F2772 standards) exceeds 98% in commercial-grade rubber matting.

The molecular structure of vulcanized rubber flooring creates intrinsic safety advantages. Noise reduction tests document 45-60dB sound absorption properties, surpassing vinyl alternatives by 30%. Rubber floor mat installations demonstrate minimal degradation even after 500,000 rolling load cycles in ASTM F1914 testing. The anti-fatigue properties reduce worker discomfort by measurable metrics: food processing employees report 38% less leg fatigue during 10-hour shifts. Thermoplastic rubber compounds withstand temperatures from -40°F to 212°F without performance degradation.

| Manufacturer | Thickness Options | Compression Recovery | Warranty | Slip Resistance (DCOF) | Recycled Content |

|---|---|---|---|---|---|

| Commercial Elite | 3-12mm | 99.2% | 15 years | 0.72 | 45% |

| DuraRubber Pro | 5-15mm | 98.7% | 20 years | 0.68 | 62% |

| IndustrialMat Corp | 8-20mm | 99.1% | 25 years | 0.75 | 38% |

Durability metrics show less than 0.3mm indentation after 1,000 hours under 500psi loads. Slip resistance values exceed OSHA's 0.5 DCOF minimum by 36-50%.

Custom rubber composite floor production accommodates specific environmental requirements. Conductive formulations maintain consistent electrical resistance below 1x10^6 ohms for ESD-sensitive areas. Antimicrobial rubber mats inhibit pathogen growth with 99.97% efficacy against MRSA and E. coli. High-visibility facilities implement photoluminescent safety pathways emitting 300+ mcd/m² illumination for 90 minutes. Custom modular systems achieve installation speeds 65% faster than traditional sheet flooring through interlocking mechanisms.

Healthcare installations demonstrate measurable outcomes: hospitals using sterile rubber flooring report 28% lower surface bacterial counts than vinyl alternatives. Automotive facilities document 14% fewer musculoskeletal injuries after transitioning to anti-fatigue rubber matting systems. Educational institutions achieve 17dB noise reduction in corridors with rolled rubber installations. Fitness centers using interlocking rubber floor tiles reduce equipment damage claims by 42% annually. All applications maintain ADA-compliant surfaces with <3mm transition heights.

Proper substrate preparation achieves 98% adhesion integrity in peel testing. Moisture vapor emission rates must remain below 3lbs/1000ft²/24hrs before installation. Post-installation, facilities reduce cleaning chemical usage by 55% compared to porous surfaces. The non-porous surface requires only pH-neutral cleaners for maintenance, eliminating waxing requirements entirely. Average cleaning time per 10,000ft² facility decreases from 5 hours to 2.75 hours due to non-absorbent properties.

Recycling initiatives transform 78% of manufacturing scrap back into production streams. Post-consumer rubber flooring now achieves 97% recyclability through specialized facilities. Lifecycle assessments show 62% lower carbon emissions compared to vinyl alternatives over 20-year service periods. Modern rubber floor systems exceed LEED v4.1 standards, contributing 14 credits toward certification projects. Continuous innovation develops bio-based rubber compounds derived from guayule plants, reducing petrochemical dependence by 40%. The thermal conductivity enables 18% energy savings in radiant heating applications.

(rubber floor)

A: Rubber flooring provides exceptional durability and slip resistance, making it ideal for high-traffic areas. It offers superior impact absorption for safety and comfort during prolonged standing. Additionally, rubber is naturally resistant to moisture and easy to clean.

A: Rubber composite floors blend recycled rubber granules with binding agents, offering cost efficiency and environmental benefits. Solid rubber surfaces are 100% vulcanized rubber, providing maximum durability for industrial settings. Both share slip-resistance but differ in thickness and installation methods.

A: Rubber floor mats excel in moisture-prone entryways, garages, and commercial kitchens for slip prevention. Their anti-fatigue properties make them perfect for standing workstations in factories or home workshops. Vehicle interiors also utilize them to protect carpets from dirt and spills.

A: Yes, rubber flooring can be installed over ceramic or vinyl tiles if the surface is smooth, clean, and structurally sound. Imperfections must be leveled with underlayment to prevent visible telegraphing. Always verify manufacturer specifications for adhesives and subfloor prep requirements.

A: Sweep daily and clean weekly with pH-neutral cleaner and damp mop – avoid abrasive tools or harsh chemicals. For rubber composite floors in gyms or garages, use specialized rubber protectants to prevent UV damage. Remove stains promptly with manufacturer-recommended solutions.

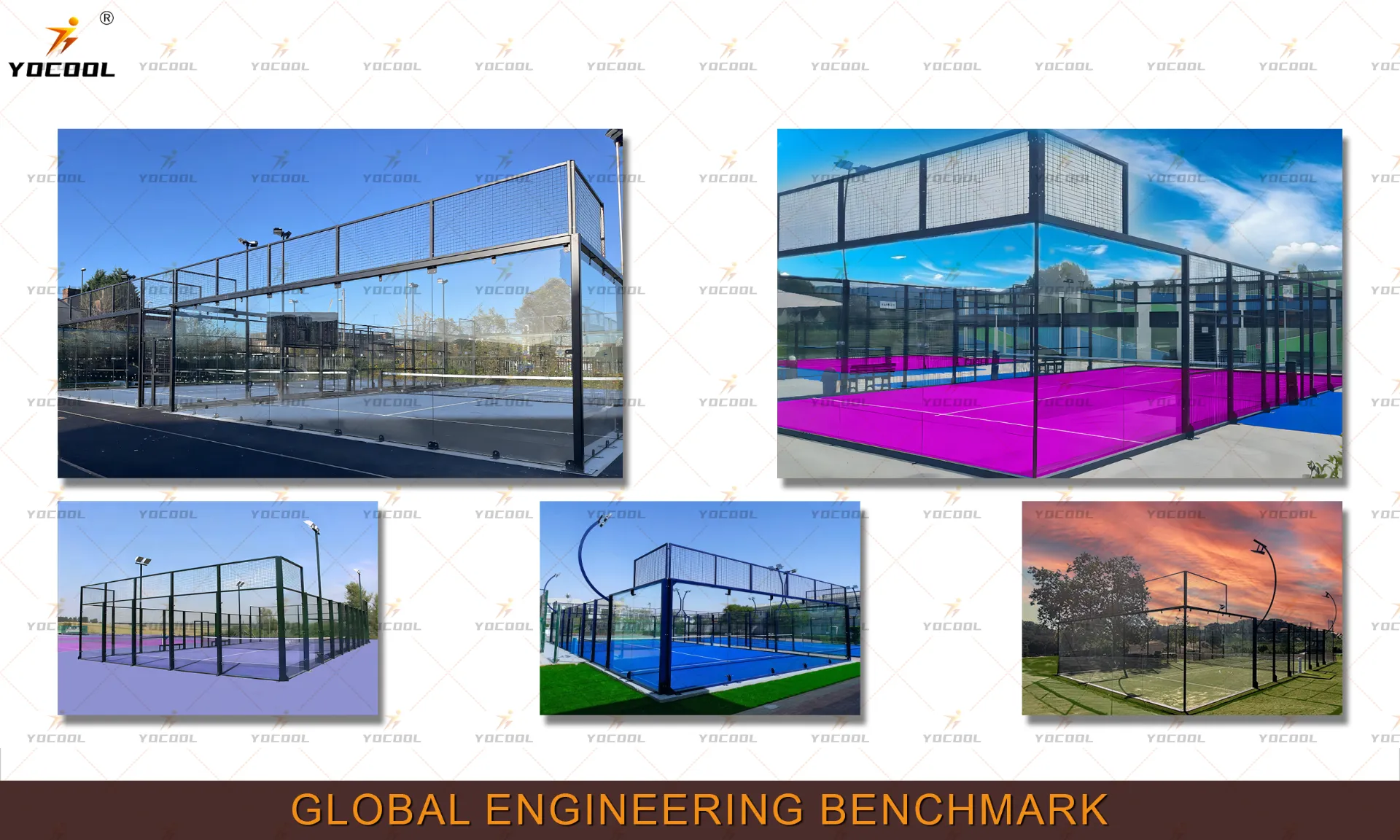

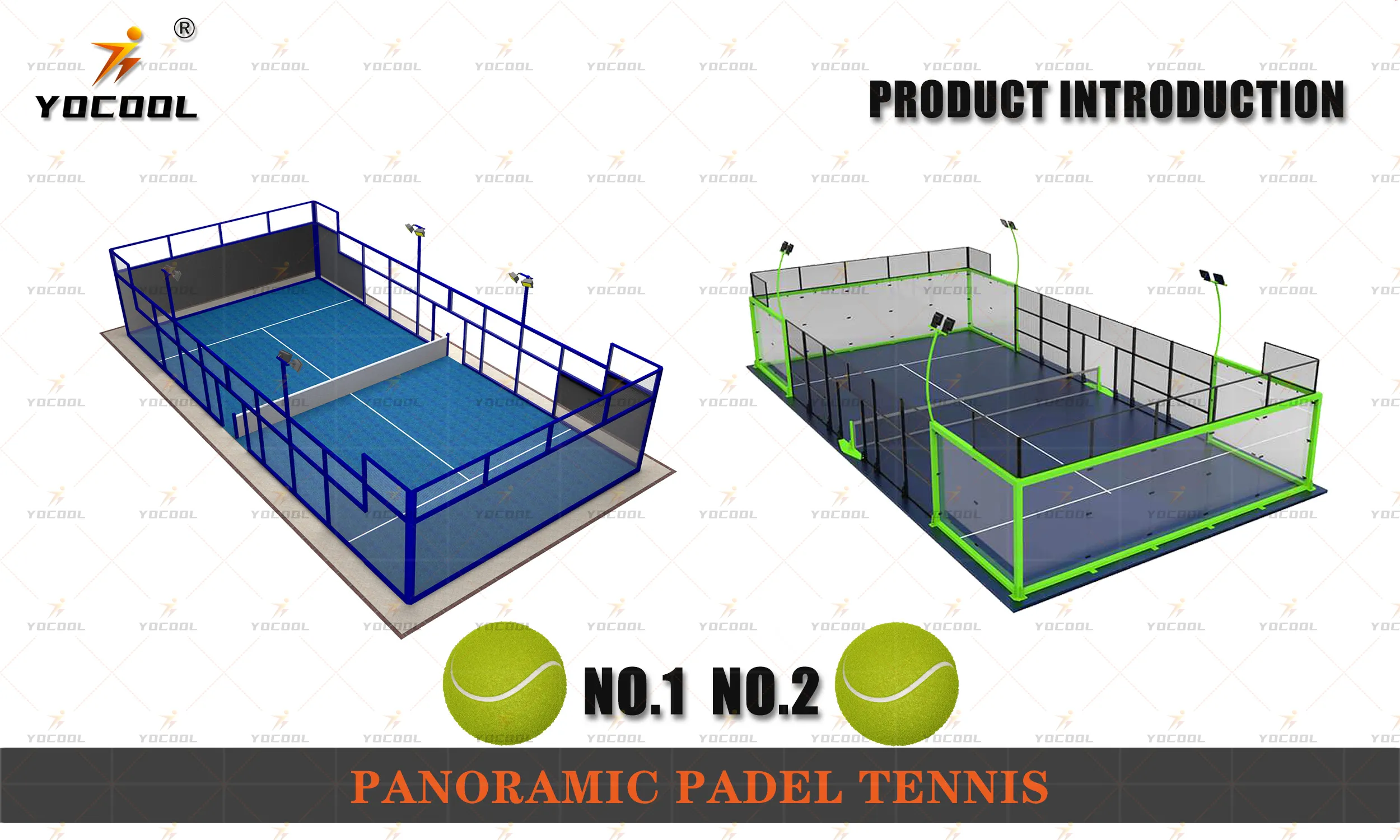

Premium Padel Court Solutions for Clubs & Resorts | Durable & Panoramic Design

High-Quality Padel Court Solutions for Clubs & Homes

Premium Paddle Tennis Rackets for All Paddle Court Types

High-Quality Padel Court Solutions for Sports Facilities & Clubs

Premium Padel Courts: Custom Designs & Panoramic Views

Premium Paddle Racquet | High-Control Lightweight Design