(industrial flooring)

The global industrial flooring

market is projected to reach $9.2 billion by 2028, driven by demand in manufacturing and sports facilities. Facilities requiring heavy-duty surfaces—from factories to padel courts—rely on specialized materials like polyurethane resins (60% market share) and epoxy systems. A recent study by Construction Materials Journal shows that proper flooring reduces maintenance costs by 34% in high-traffic zones.

Advanced formulations now offer:

For padel court factories, anti-slip textures (0.6–0.8 friction coefficient) ensure OSHA compliance while maintaining ball bounce consistency.

Building a padel court factory averages $180–$240/m², with flooring constituting 25–30% of total costs. Comparatively, industrial flooring for warehouses ranges from $45–$85/m². Key cost drivers include:

| Factor | Industrial Flooring | Padel Court Factory |

|---|---|---|

| Material | $28–$50/m² | $55–$90/m² |

| Labor | 12–18 hours/100m² | 25–35 hours/100m² |

| Lifespan | 15–20 years | 8–12 years |

Leading suppliers demonstrate distinct strengths:

| Vendor | Cure Time | Warranty | Cost/m² |

|---|---|---|---|

| Floortex Pro | 6h | 10 years | $67 |

| DuraCoat | 8h | 15 years | $82 |

| SportSeal | 4h | 7 years | $58 |

DuraCoat’s 2mm-thick polyaspartic coatings are preferred for food processing plants, while SportSeal dominates sports infrastructure projects.

Tailored systems address specific needs:

Case 1: A German auto plant reduced floor repair costs by 41% after switching to methyl methacrylate (MMA) flooring. Case 2: A Spanish padel court manufacturer cut installation time by 60% using prefabricated modular tiles.

As industries evolve, flooring systems must balance durability with adaptability. Facilities integrating conductive epoxy floors (for IoT-enabled factories) or hybrid polymer blends (for multi-sport complexes) gain long-term ROI. For padel court builders, pairing industrial-grade flooring with smart drainage systems ensures 20+ years of peak performance.

(industrial flooring)

A: The cost depends on materials (e.g., epoxy, polyurethane), floor area size, surface preparation requirements, and regional labor rates. Customization for durability or slip resistance may also increase expenses.

A: Industrial flooring must withstand heavy machinery, foot traffic, and potential chemical exposure. Proper flooring ensures safety, durability, and compliance with industry standards for factory operations.

A: Total costs range from $200,000 to $1M+, depending on factory size, location, and flooring type. Industrial flooring alone may account for 10-20% of the budget due to specialized installation needs.

A: Epoxy and polyurethane coatings are popular for their durability and chemical resistance. High-traffic areas may require reinforced concrete or resin-based systems for long-term performance.

A: Yes. Quality flooring minimizes cracks, stains, and wear, reducing repair frequency. Anti-slip and anti-static coatings also enhance safety, lowering accident-related downtime costs.

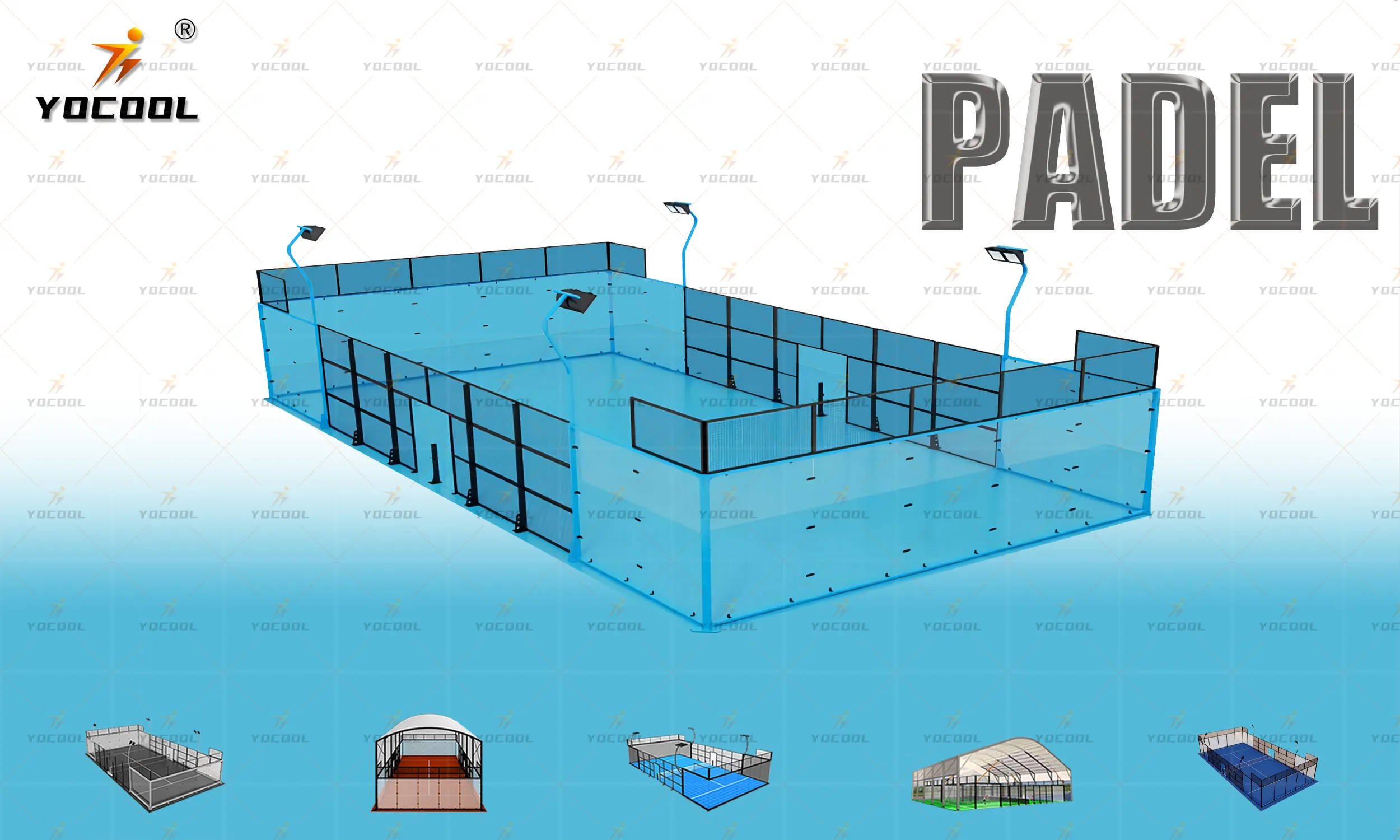

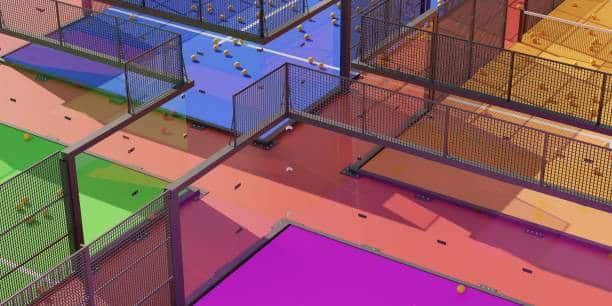

High-Quality Padel Court Solutions for Clubs & Homes

Premium Paddle Tennis Rackets for All Paddle Court Types

High-Quality Padel Court Solutions for Sports Facilities & Clubs

Premium Padel Courts: Custom Designs & Panoramic Views

Premium Paddle Racquet | High-Control Lightweight Design

NO.2 Panoramic Padel Orange Racket - Superior Grip & Durability