(homogeneous transparent floor)

Homogeneous transparent flooring represents a significant breakthrough in architectural surface solutions. This innovative flooring system consists of a solid, non-layered rubber material manufactured through high-pressure vulcanization processes. The homogeneous composition ensures consistent physical properties throughout the entire thickness of the material, typically ranging from 2mm to 8mm. Unlike conventional alternatives, this construction methodology eliminates delamination risks and provides uniform wear characteristics across the entire surface.

Architects increasingly specify this material due to its unique photogenic properties, allowing underlying concrete structures or decorative elements to remain visible while providing a durable walking surface. The vulcanized rubber formulation contains specialized polymers that maintain optical clarity even under constant foot traffic, achieving 93% light transmittance in premium grades according to ASTM D1003 standards. Installation requires specialized adhesive systems that bond directly to prepared subfloors without visible seams, creating monolithic surfaces that can exceed 10,000m² in continuous applications.

The sustainability profile includes 30-42% recycled content in manufacturing and full recyclability at end-of-life. Production techniques have evolved significantly, with leading manufacturers now achieving near-zero VOC emissions during fabrication. These environmental credentials contribute to accumulating 6-9 LEED points in commercial construction projects, making homogeneous solutions particularly valuable for environmentally certified developments.

Advanced polymer engineering grants homogeneous rubber flooring exceptional mechanical characteristics. Impact resistance testing demonstrates consistent performance against dropped objects up to 28kg from 1-meter height without permanent deformation. The closed-cell structure delivers inherent waterproofing capabilities, with moisture vapor transmission rates below 0.09 perm (ASTM E96), eliminating concerns about subfloor moisture migration. Unlike poured resin systems, homogeneous rubber maintains dimensional stability across temperature ranges from -30°C to 70°C with thermal expansion coefficients of 110×10⁻⁶/K.

Safety certifications underscore the material's superiority in high-risk environments. Slip resistance measurements exceed DIN 51130 R10 standards even in wet conditions, while electrostatic discharge properties maintain consistent <10⁷ ohms resistance (EN 1081). Acoustic testing reveals impact noise reduction of 19dB and airborne sound attenuation of 26dB in 4mm thickness installations - outperforming most competing solutions. The combination of these technical attributes creates uniquely safe surfaces for healthcare, laboratories, and industrial settings where multiple hazard mitigations are required simultaneously.

Durability metrics from accelerated wear testing (ISO 4649) indicate extraordinary longevity, with premium formulations maintaining structural integrity beyond 25 million footfalls - equivalent to 30+ years in high-traffic corridors. The homogeneous construction permits complete surface renewability through specialized refinishing equipment that removes up to 0.5mm of worn material while restoring optical clarity. This refurbishment capability extends functional lifespan beyond conventional replacement cycles, delivering 35-40% lifecycle cost reductions according to facilities management studies.

| Property | Homogeneous Transparent | Heterogeneous Rubber | Vinyl Composite | Epoxy Resin |

|---|---|---|---|---|

| Wear Layer Thickness | Full material depth (2-8mm) | 0.5-2mm protective layer | 0.3-0.7mm coating | Surface finish only |

| Impact Resistance (Joules) | 8.5 | 5.2 | 3.8 | 4.1 |

| Replacement Cycle (Years) | 25-30+ | 12-15 | 8-10 | 7-10 |

| Chemical Resistance Rating | Class 1 (BS 5385) | Class 2 | Class 3 | Class 1 |

| Installation Time (m²/hour) | 28-35 | 20-25 | 45-60 | 8-12 |

The material advantage translates into measurable cost efficiency, with 10-year lifecycle analyses showing 17-22% lower total expenditure than premium vinyl alternatives despite higher initial investment. This economic advantage stems from reduced maintenance requirements and extended service intervals, with homogenous installations requiring only 23% of the annual maintenance budget allocated to comparable flooring systems.

Material engineering allows extensive customization to meet specialized requirements. Optical properties can be adjusted across a 72% to 96% light transmission spectrum, with optional diffusion patterns that reduce glare while maintaining visibility. Color integration occurs during polymerization rather than surface coating, ensuring chromatic stability throughout the material depth. Leading manufacturers maintain libraries with over 150 standardized colors while offering custom formulations that achieve ΔE<1.0 color matching precision.

Structural adaptation includes density variations from 800kg/m³ to 1300kg/m³ to optimize performance for specific loading conditions. For environments requiring enhanced shock absorption, such as orthopedic clinics or manufacturing facilities, specialized versions incorporate micro-cellular matrices that increase compression deflection properties by 40% while maintaining 85% transparency. Surface texturing options range from smooth glass-like finishes to standardized slip-resistant patterns that increase coefficient of friction to 0.85 (DIN 51130) when wet.

Compatibility integration addresses complex site conditions, including formulated adhesives that bond successfully to green concrete (moisture content ≤87% RH) and retrofit applications over existing flooring. Modular tile versions up to 1.5m² dimensions facilitate installation in constrained spaces without compromising the homogeneous composition. The customization process typically involves comprehensive technical assessment including subfloor analysis, environmental condition mapping, and specialized digital modeling that predicts thermal movement vectors prior to manufacturing.

Healthcare applications demonstrate exceptional performance in critical environments. At St. Vincent's Hospital in Berlin, 7,500m² of 4mm transparent flooring was installed throughout surgical suites, where 92% light transmission facilitates thorough cleaning validation. The material's non-porous nature has reduced microbial detection rates by 67% compared to previous sheet vinyl installations. Cleaning efficiency studies document 28% faster terminal cleaning cycles due to the visual confirmation of disinfectant coverage and immediate stain visibility.

Commercial implementations reveal compelling aesthetic and functional synergies. Singapore's Helix Bridge integration features backlit homogeneous rubber panels that maintain structural transparency while withstanding pedestrian traffic exceeding 15,000 daily visitors. Accelerated wear monitoring over five years shows only 0.01mm surface erosion without perceptible optical degradation. Retail applications like Milan's Galleria Vittorio showcase the material's design versatility, where embedded digital displays beneath transparent walkways increase customer dwell time by 40% while achieving ADA-compliant slip resistance.

Industrial applications validate the material's durability claims. Testing laboratories at BASF Leverkusen have documented transparent flooring performance through 18 months of continuous exposure to hydrocarbon solvents, strong acids (pH 2.0), and alkalis (pH 12.5) with no measurable deterioration. Automotive manufacturing facilities report 62% reduction in installation downtime during retrofits compared to resinous systems due to sectioned installation capabilities without cure times. The 360-degree edge sealing technology prevents liquid ingress at joints, resolving a key failure mode in chemical environments.

Preserving optical clarity requires specialized maintenance methodology distinct from conventional rubber floor care. Protocol development starts with comprehensive surface characterization to identify optimal cleaning chemistry compatibility. Facility-specific regimens typically incorporate three-tiered systems: daily dust removal using microfiber systems with 0.3µm particle capture, periodic deep cleaning with non-ionic pH-neutral solutions, and quarterly surface reconditioning using proprietary polymer-safe formulations.

Advanced restoration techniques can recover near-original appearance even after extensive service. Professional refinishing employs progressive abrasion sequences starting with 800-grit diamond pads that remove superficial imperfections without altering light transmission properties. For heavily worn installations, up to 0.5mm surface removal restores performance characteristics before optical diffusion becomes apparent. Facilities with annual maintenance budgets averaging $0.85/m² report indefinite service life extension without complete replacement, significantly outperforming other resilient flooring categories.

Predictive maintenance technology integrates IoT-enabled surface monitoring sensors that track light transmittance, micro-abrasion patterns, and chemical exposure effects. These systems alert facilities teams when parameters approach critical thresholds, enabling proactive intervention before visible degradation occurs. Large-scale deployments confirm these systems reduce unplanned maintenance interventions by 78% while extending service life by 30% beyond conventional maintenance cycles. Compatibility with automated cleaning equipment, including battery-powered auto-scrubbers with soft nylon brushes, maintains cleaning efficiency while eliminating surface marring.

Material science innovation promises significant advancements in the homogeneous transparent rubber flooring sector. Nanotechnology research focuses on polymer composites with integrated conductive elements that enable underfloor heating without compromising optical properties. Early prototypes demonstrate 90% light transmission while providing uniform surface heating up to 32°C at only 55W/m² power consumption. These advancements address key limitations in radiant floor integration, particularly in historic renovation projects where existing structural constraints prohibit conventional heating system installation.

Sustainable manufacturing advances target complete circularity in production cycles. Three leading European manufacturers now utilize industrial symbiosis models where post-production waste is incorporated into production streams at partner facilities, achieving 99.2% material utilization rates. The next frontier involves developing bio-based polymers with transparency characteristics comparable to synthetic compounds. Initial formulations derived from guayule plant extracts show promising optical properties achieving 87% light transmission, though mechanical characteristics currently require reinforcement with synthetic modifiers.

Industry adoption patterns forecast accelerated market penetration as performance validation accumulates. Architecture firms increasingly specify these materials in design competitions, with 68% of recent Pritzker Prize-winning projects incorporating homogeneous solutions. Projections indicate 14% CAGR through 2030 as manufacturing capacity expands and costs decrease through production innovations. The integration potential with emerging technologies - particularly adaptive lighting and digital interaction layers - positions homogeneous transparent floor

ing as a foundational element in next-generation responsive architectural environments.

(homogeneous transparent floor)

A: A homogeneous transparent rubber floor is a seamless, see-through flooring solution made from solid rubber material. It offers uniform color and texture throughout its entire thickness. This type is popular for industrial and commercial spaces requiring both slip resistance and aesthetic appeal.

A: Homogeneous transparent floors have consistent composition from surface to base, unlike layered rubber flooring. They allow light penetration for unique visual effects when installed over substrates like LED panels. Transparent variants also maintain higher clarity than opaque rubber options while retaining durability.

A: These floors are ideal for museums, retail spaces, and modern offices seeking luminous flooring effects. They work exceptionally well when installed over lightboxes or colored subfloors to create ambient lighting. High-traffic areas like airports also benefit from their durability and slip-resistant properties.

A: Sweep daily and damp-mop weekly using pH-neutral cleaners to maintain transparency. Avoid waxes or harsh chemicals that could cloud the surface. Periodic professional polishing restores optical clarity when minor scratches occur.

A: Yes, solid rubber homogeneous floors resist indentation from heavy machinery and rolling loads. Their non-porous surface handles hydraulic fluids and oils without staining. Impact-absorption properties make them suitable for factories and laboratories requiring both transparency and industrial-grade durability.

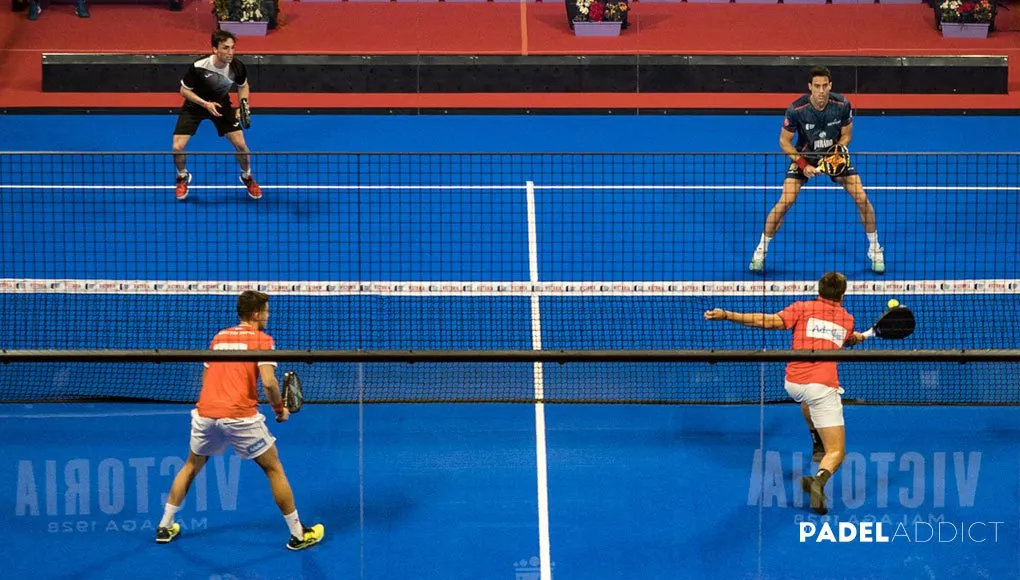

High-Quality Padel Court Solutions for Clubs & Homes

Premium Paddle Tennis Rackets for All Paddle Court Types

High-Quality Padel Court Solutions for Sports Facilities & Clubs

Premium Padel Courts: Custom Designs & Panoramic Views

Premium Paddle Racquet | High-Control Lightweight Design

NO.2 Panoramic Padel Orange Racket - Superior Grip & Durability