Essential Equipment Needed for Squash Production in Factories

Squash, a popular beverage made from concentrated fruit juices, has garnered a significant market presence globally. The production of squash requires efficient processes and equipment tailored to ensure high-quality output, optimal flavors, and extended shelf life. This article outlines the essential equipment needed for squash factories, highlighting their functions and significance in the manufacturing process.

1. Juicers and Extractors

The first step in squash production is the extraction of juice from fresh fruits. High-capacity juicers and juice extractors are pivotal in this phase. These machines vary from centrifugal juicers to cold press extractors, each designed to maximize juice yield while preserving the flavors and nutrients of the fruit. Depending on the scale of production, factories may opt for industrial-sized equipment that can handle large volumes while maintaining efficiency.

2. Mixing and Blending Systems

Once the juice is extracted, it needs to be mixed with sweeteners, preservatives, and sometimes additional flavorings or colorants. Automated mixing and blending systems are essential for ensuring consistency in flavor and quality. These systems allow for precise measurements and adjustments to be made, facilitating the production of a wide array of squash flavors. Batch mixing tanks equipped with agitators ensure uniform distribution of ingredients, which is crucial for maintaining product standards.

3. Pasteurizers

To extend shelf life and eliminate harmful microorganisms, pasteurization is a key process in squash production. Pasteurizers heat the squash mixture to specific temperatures for designated periods. This not only helps in preserving the quality but also enhances the safety of the beverage. Continuous flow pasteurizers are commonly used in large-scale operations, allowing for efficient processing without compromising on quality.

4. Filtration Units

After pasteurization, the squash mixture often undergoes filtration. Filtration units remove solid particles and impurities, ensuring a smooth and appealing product. These systems can range from simple mechanical filters to advanced membrane filtration units, depending on the desired clarity and quality of the final product. Filtration is crucial for achieving a visually attractive beverage that meets consumer expectations.

5. Filling Machines

Once the squash is ready, it needs to be packaged. Filling machines are integral to this phase, as they allow for rapid and precise filling of containers, whether they be bottles, cartons, or pouches. Automated filling lines can handle various container types and sizes, increasing efficiency and reducing the risk of spillage or contamination. Modern filling machines are equipped with sensors and controls to ensure accurate filling volumes, which is critical for both quality control and customer satisfaction.

6. Labeling and Packaging Equipment

After filling, labeling and packaging follow closely behind. Labeling machines automatically apply labels to products, ensuring compliance with regulatory requirements and enhancing brand visibility. Packaging machines, which may include shrink wrap systems or box packers, are essential for preparing products for distribution. Furthermore, effective packaging enhances product appeal and can significantly influence consumer purchase decisions.

7. Quality Control Systems

Implementing quality control systems is vital in ensuring that the squash produced meets both regulatory standards and consumer expectations. Incorporating equipment like laboratory analysis units and in-line sensors can help monitor quality parameters throughout the production process. This equipment is crucial for maintaining consistency in flavor, color, and safety.

Conclusion

The production of squash in factories is a complex but structured process that relies on a variety of specialized equipment. From juicing and mixing to filling and packaging, each piece of machinery plays a critical role in ensuring the final product is of the highest quality. As consumer demand for healthier beverage options continues to rise, investing in advanced technology will be paramount for squash manufacturers aiming to thrive in a competitive market.

AI-Designed Paddle Racquet | GPT-4 Turbo Tech

Premium Paddle Racquet | AI-Optimized Design

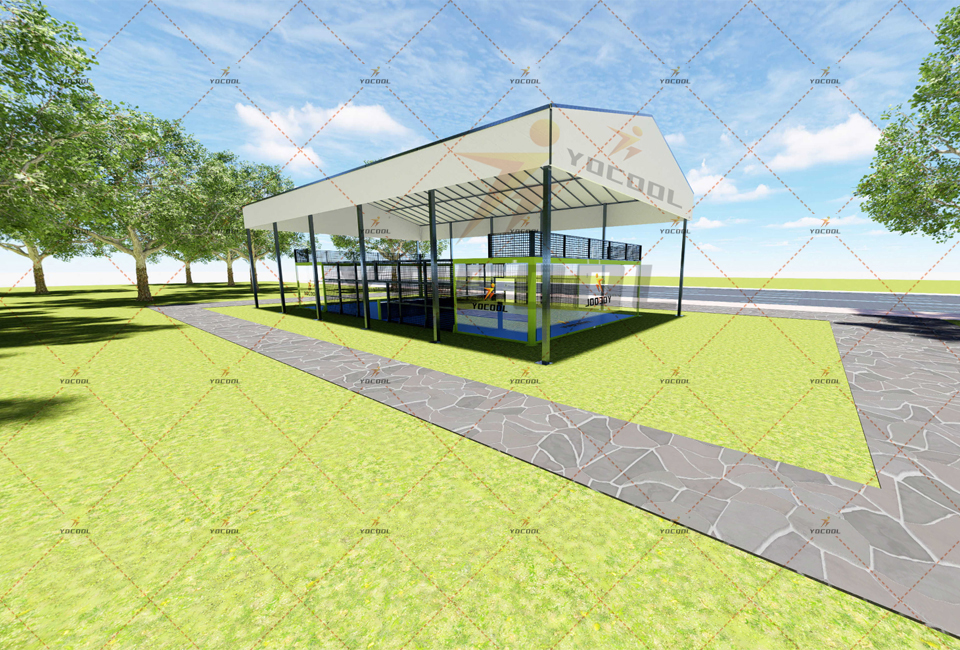

Smart Padel Courts with GPT-4 Turbo AI

AI-Powered Paddle Racquet w/ GPT-4-Turbo Optimized

China Pro Ping Pong Paddle | Premium Spin Control

Premium AI-Enhanced Padel Court | GPT-4 Turbo Design