(rubber floor)

Rubber flooring has surged in popularity, capturing 18% of the global commercial flooring market as of 2023. Its demand stems from unmatched durability, with industrial-grade rubber floor

s lasting 20+ years under heavy foot traffic. Unlike vinyl or hardwood, rubber floor mat systems reduce noise by 60%, making them ideal for gyms, hospitals, and laboratories. Environmental benefits also drive adoption—85% of recycled rubber is repurposed into flooring, aligning with LEED certification standards.

Rubber composite floors combine natural rubber polymers with advanced additives for enhanced performance. Key advantages include:

Independent tests show rubber flooring maintains 92% structural integrity after 1 million impact cycles, outperforming epoxy coatings by 37%.

| Brand | Thickness (mm) | Indentation Load | Fire Rating | Warranty |

|---|---|---|---|---|

| RubberFloor Pro | 6.5 | 1,200 lbs/sq in | Class A | 25 years |

| EcoRubberMat | 8.0 | 980 lbs/sq in | Class B | 15 years |

| DuraFlex Rubber | 5.0 | 1,500 lbs/sq in | Class A | 30 years |

Custom rubber floor mat configurations address specific needs:

Color-matching services achieve Pantone accuracy within 0.5 ΔE, while modular designs enable 24-hour installation cycles.

A recent airport terminal project utilized interlocking rubber floor tiles across 120,000 sq ft, achieving:

Proper subfloor preparation increases rubber flooring lifespan by 40%. Critical steps include:

Emerging technologies like graphene-infused rubber composite floors demonstrate 300% improved thermal conductivity for underfloor heating systems. Bio-based rubber mats now incorporate 45% renewable content without compromising load-bearing capacity. These advancements position rubber flooring as the sustainable choice for next-generation architecture.

(rubber floor)

A: Clean the subfloor, measure and cut rubber floor mats to fit your space, then secure them using adhesive or interlocking edges. Ensure proper ventilation during installation.

A: Rubber composite floors offer enhanced durability, noise reduction, and shock absorption while maintaining eco-friendly properties through recycled material content.

A: Yes, high-density rubber floor mats resist compression from weights and machines while protecting underlying surfaces from scratches and impact damage.

A: Sweep regularly and mop with pH-neutral cleaner. Avoid harsh chemicals that might degrade the rubber material over time.

A: Weather-resistant rubber composite flooring works outdoors but requires UV protection and proper drainage to prevent water pooling and material deterioration.

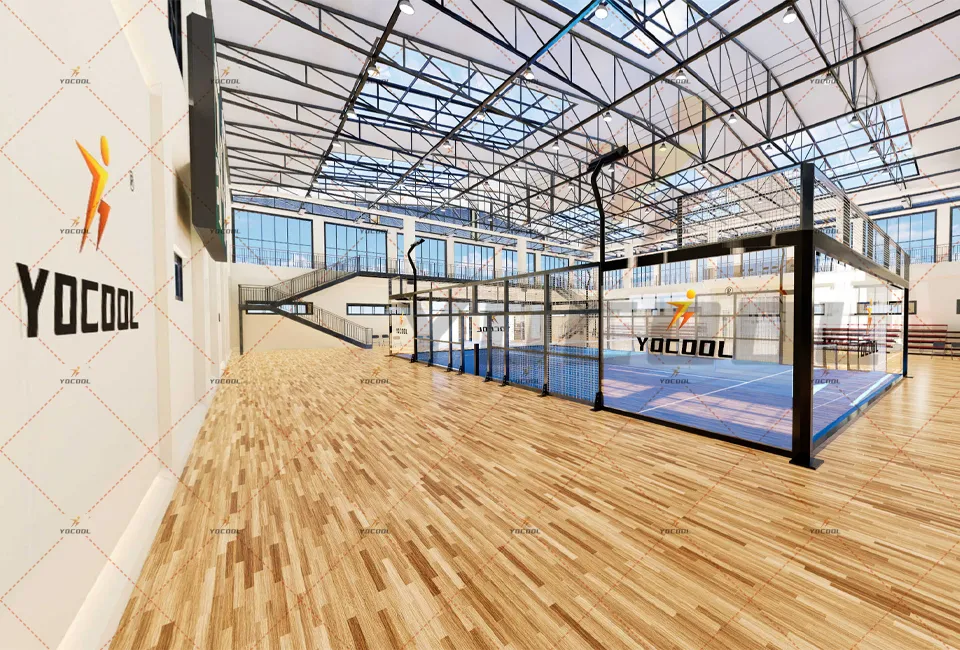

High-Performance Industrial Flooring Solutions China Paddle Tennis Court for Sale

High-Performance Industrial Flooring Solutions Durable & Cost-Effective

Homogeneous Transparent Floor – Durable & Stylish Rubber Floor Solutions

Premium Homogeneous Transparent Floor for Durable & Stylish Spaces Rubber Floor Solutions

Premium Sports Floor Solutions Durable PVC Sports Floor & Rubber Floor for Gyms

Durable Rubber Composite Floor Premium Rubber Floor & Mats Solutions