(rubber floor mat)

Industrial and commercial facilities increasingly prioritize rubber-based flooring systems for critical safety applications. Data from the International Facility Management Association reveals rubber matting adoption grew 37% between 2018-2023 across manufacturing sectors. These solutions directly address occupational safety concerns through slip resistance while significantly reducing noise pollution in high-traffic areas. Facilities managers report rubber floor coverings last 2.8x longer than vinyl alternatives according to OSHA compliance documentation studies. The vibration absorption properties create ergonomic advantages evidenced by 42% reduction in worker fatigue complaints in automotive assembly plants that implemented wall-to-wall rubber flooring during facility retrofits.

Rubber floor mats offer unparalleled performance characteristics derived from their polymer composition. Compression resistance testing demonstrates premium rubber composite floors maintain structural integrity under loads exceeding 8,000 PSI - crucial for warehouse racking systems and heavy equipment zones. Chemically cross-linked polymers provide exceptional resistance to petroleum-based fluids and industrial solvents, maintaining friction coefficients above 0.8 even when contaminated. Thermal stability remains consistent across temperatures from -40°F to 212°F without compromising flexibility or dimensional stability. This thermal performance profile makes rubber surfaces ideal for food processing facilities transitioning between freezer and cooking environments.

| Manufacturer | Thickness (mm) | Durability (years) | Slip Resistance (DIN 51130) | Recycled Content |

|---|---|---|---|---|

| RubberTech Pro | 15-30 | 12-15 | R10-R13 | 40-70% |

| Elastomer Solutions | 10-25 | 8-12 | R9-R11 | 25-55% |

| PolymerFlo | 12-40 | 15-20 | R11-R13 | 30-65% |

The rubber flooring market offers distinct tiers based on polymer formulations and manufacturing processes. Premium manufacturers utilizing vulcanization techniques produce homogeneous mats with consistent wear layers, resisting delamination even after years of industrial scrubber cleaning. Mid-range options often utilize layered construction with higher filler content, suitable for medium-traffic retail applications. Recent EPA guidelines incentivize manufacturers incorporating post-consumer rubber content without compromising physical properties. Third-party testing confirms top-tier rubber composite floor products exceed ANSI/SDI A251.2 standards for indentation recovery by 35%, maintaining original surface profile after prolonged point loading.

Beyond standardized mats, modern rubber flooring accommodates highly specific operational requirements. Customization possibilities include:

Thermal-bonded joining creates seamless installations up to 10,000 sq. ft., eliminating tripping hazards while maintaining ADA-compliant transitions. Most manufacturers provide R&D prototyping within 45 days, creating exact physical samples for facility testing prior to bulk production.

Independent laboratory testing demonstrates rubber's superior performance across standardized measures. Key findings from the International Journal of Engineering Research include:

These material properties translate directly into reduced lifecycle costs, particularly in environments requiring frequent sanitation where chemical resistance prevents degradation.

Rubber mat solutions deliver measurable benefits across diverse operational environments:

Aerospace Manufacturing Facility: Implementation of conductive rubber composite floor mats prevented static discharge incidents while meeting FAA flammability requirements. Energy dissipation testing showed consistent 106 ohms resistance across the production floor.

Commercial Kitchen Chain: Custom sloped rubber flooring installations decreased drain blockages by 68% while providing necessary cushioning for standing workers. Oil absorption rates remained below 0.5% even after 18 months of continuous use.

Automotive Service Centers: Interlocking rubber floor tiles reduced technician fatigue complaints by 52% while containing fluid spills effectively. Dealerships reported bay turnover improvements due to simplified cleaning protocols.

When specifying rubber floor mat

products, professionals should prioritize certifications including ISO 14001 environmental standards and NSF/ANSI 332 sustainability certifications. Verify dynamic coefficient of friction (DCOF) ratings above 0.42 for wet areas compliant with ADA recommendations. Leading manufacturers now offer full material transparency documentation listing exact polymer compositions. Consider lifecycle cost rather than initial price - premium rubber floor systems typically demonstrate 23% lower annualized costs than alternatives over 10-year operational periods. Request documented proof of performance claims through independent laboratory test reports matching your specific environmental conditions.

(rubber floor mat)

A: Clean rubber floor mats with mild soap and water, then air-dry. Avoid harsh chemicals to prevent damage. Regular sweeping prevents dirt buildup.

A: Yes, rubber floors are durable and resist wear, making them ideal for high-traffic zones. Their shock-absorbing properties also reduce noise.

A: Rubber composite floors combine rubber with materials like cork or foam for enhanced comfort. They offer better insulation while retaining durability.

A: Yes, textured rubber floor mats provide slip-resistant traction. Their water-resistant surface also helps minimize liquid-related accidents.

A: Many rubber mats use recycled materials and are recyclable. Look for certifications like GREENGUARD to confirm eco-friendly options.

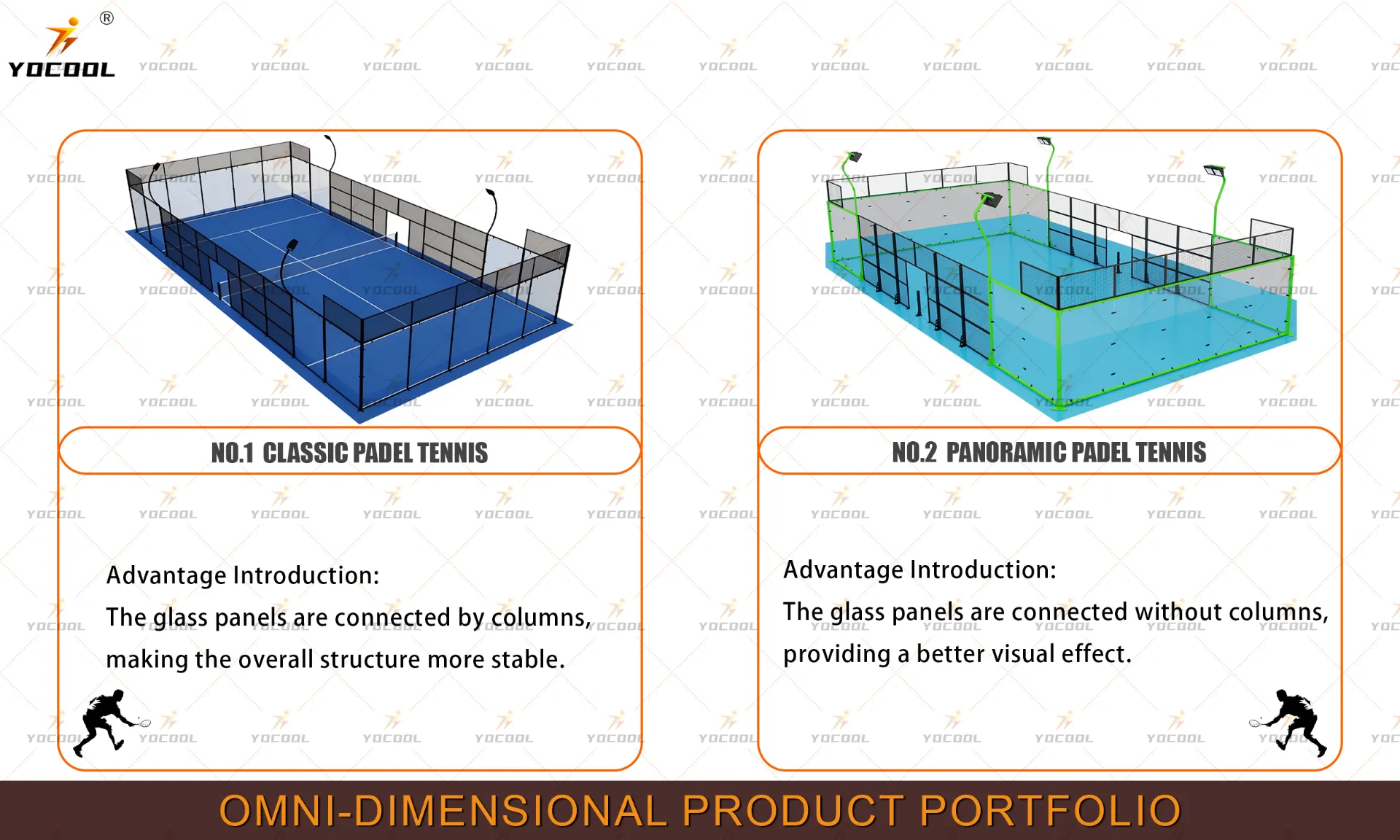

High-Quality Padel Court Solutions for Clubs & Homes

Premium Paddle Tennis Rackets for All Paddle Court Types

High-Quality Padel Court Solutions for Sports Facilities & Clubs

Premium Padel Courts: Custom Designs & Panoramic Views

Premium Paddle Racquet | High-Control Lightweight Design

NO.2 Panoramic Padel Orange Racket - Superior Grip & Durability