Understanding the Costs of Manufacturing a Paddle Tennis Court

Paddle tennis, an engaging racket sport that combines elements of tennis and squash, has gained popularity worldwide. As the sport continues to grow, the demand for paddle tennis courts is on the rise. For manufacturers and sports facility developers, understanding the costs associated with creating a paddle tennis court is essential to make informed decisions. This article will explore the key factors influencing the cost of manufacturing a paddle tennis court, including materials, construction, and additional amenities.

Key Components of Paddle Tennis Court Manufacturing

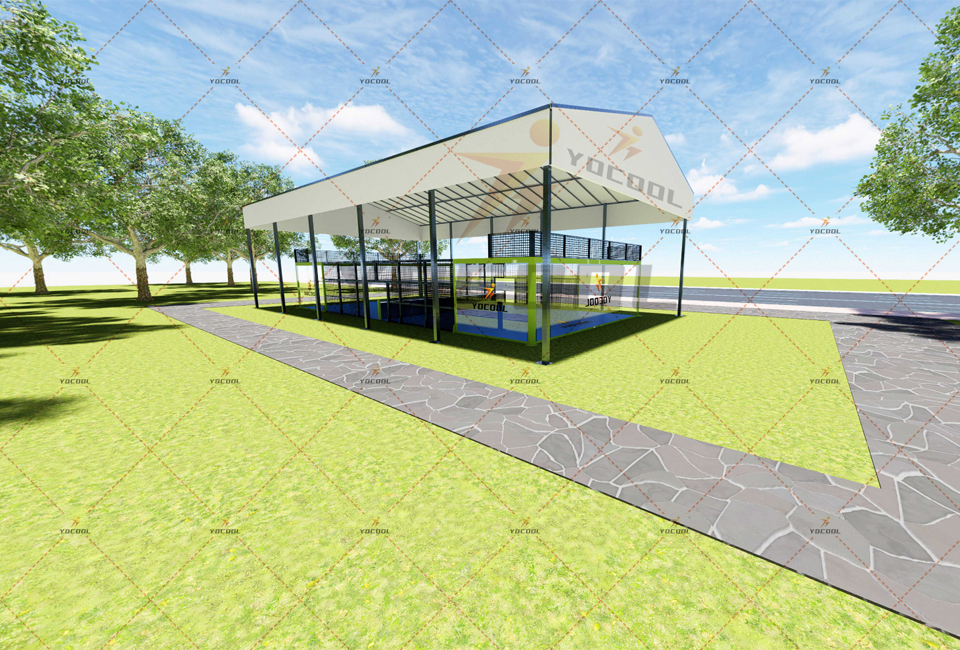

1. Court Dimensions and Design The standard size of a paddle tennis court is approximately 10 meters wide and 20 meters long, enclosed by walls made of either glass or solid materials. The area must also accommodate necessary space for player movement. The complexity of the design can significantly affect costs; for instance, opting for a fully enclosed court with glass walls will demand higher investment compared to a more straightforward, open-air model.

2. Surface Materials The choice of playing surface greatly influences the overall cost. Common surface materials include artificial turf, acrylic coatings, or traditional asphalt and concrete. When selecting materials, it's vital to consider durability, maintenance requirements, and player comfort. While high-quality surfaces may come at a premium, they can provide better performance and longevity, potentially reducing long-term costs associated with repairs and replacements.

3. Construction Costs Construction costs can vary widely depending on location, labor rates, and the complexity of the installation. Engaging experienced contractors familiar with paddle tennis court construction is crucial to ensure proper installation, which can prevent costly mistakes and delays. Labor costs can also be influenced by local regulations and the need for permits, which must be factored into the total expenditure.

4. Lighting and Amenities If the paddle tennis court is intended for evening use, it will require proper lighting. Investing in high-quality LED lighting systems can enhance playability and attract more users, but this adds to the initial investment. Additionally, including amenities such as benches, water fountains, and signage can improve the overall user experience, although these also contribute to the total cost.

5. Maintenance Considerations Long-term maintenance is a crucial aspect of paddle tennis court ownership. Various surfaces require different levels of upkeep. For instance, while artificial turf may need regular grooming and infill replenishing, acrylic surfaces may require periodic repainting to maintain performance. Planning for these future expenses is essential for manufacturers and facility owners alike.

Conclusion

The manufacturing cost of a paddle tennis court encompasses numerous factors from design and materials to construction and maintenance. While the initial investment may be significant, understanding these costs can lead to better decision-making and more successful project outcomes. With the sport’s growing popularity, investing in high-quality facilities can result in increased revenue and community engagement. For manufacturers, staying updated on the best practices and innovative materials can ensure they remain competitive in an evolving market. By addressing each component carefully, stakeholders can create paddle tennis courts that not only meet players' needs but also provide sustainable returns on investment.

Smart Padel Courts with GPT-4 Turbo AI

AI-Powered Paddle Racquet w/ GPT-4-Turbo Optimized

China Pro Ping Pong Paddle | Premium Spin Control

Premium AI-Enhanced Padel Court | GPT-4 Turbo Design

High-Quality Paddle Racquet for Professional Padel and Paddle Courts

Premium Paddle Tennis Rackets for Panoramic Padel Courts