Outline of Contents:

(industrial flooring)

Global manufacturing facilities face $12.3 billion in annual productivity losses due to substandard flooring according to Industrial Safety Journal (2023). This underscores why industrial flooring selection transcends mere surface installation, impacting operational safety and output efficiency. Facilities managing heavy machinery report 41% fewer equipment malfunctions after installing advanced resinous flooring systems. The growing 5.8% CAGR in the industrial flooring market directly correlates with increased automation requiring specialized surfaces capable of withstanding sustained mechanical stress and chemical exposure.

Modern industrial flooring incorporates nano-enhanced polyaspartic coatings that cure 8 times faster than traditional epoxies while achieving 98% UV stability. These systems demonstrate remarkable 18,500 PSI compression strength yet maintain 0.48 coefficient of friction for optimal safety. Leading formulations now integrate:

Third-party testing confirms these floors maintain structural integrity after 50,000+ forklift passes, outlasting conventional concrete 3:1.

| Manufacturer | Compressive Strength | Chemical Resistance | Installation Speed | Thermal Stability |

|---|---|---|---|---|

| Florock Industrial Systems | 21,000 PSI | 650+ chemicals | 72 hrs curing | -60°F to 450°F |

| Euclid Chemical Solutions | 17,800 PSI | 520+ chemicals | 96 hrs curing | -20°F to 350°F |

| Standard Epoxy Coatings | 9,500 PSI | 220 chemicals | 168 hrs curing | 40°F to 200°F |

Specialized manufacturing environments necessitate customized flooring formulations through precise chemical compounding. For battery production facilities, static-dissipative versions reduce spark risks with 106-109 Ω resistance ratings. Food processing plants implement antimicrobial systems containing 0.3% silver-ion additives reducing bacterial growth by 99.7%. Precision calibration of slip resistance factors ensures compliance with OSHA 0.50 COF mandates, while decorative quartz blends enhance wayfinding without compromising structural performance.

Racquetball and squash factories require specialized flooring solutions that balance athletic performance metrics with manufacturing demands. During production of court surfaces, manufacturers utilize dual-cure polyurethane systems achieving precise 45-50 Asker-C hardness ratings while maintaining critical ball rebound consistency between 80-85% of drop height. Impermeable moisture barriers beneath the surface prevent sub-slab vapor transmission exceeding 3lbs/1000ft²/24hrs. Factory production floors withstand concentrated loads from 6-ton court component stamping presses while providing ergonomic relief reducing worker fatigue complaints by 62% post-installation.

Precision installation begins with diamond grinding achieving ICRI CSP 3 surface profiles before applying penetrating primers. Robotic screed units achieve 98% flatness meeting FF/FL 35 standards through laser-guided leveling. Post-installation maintenance incorporates:

Facilities implementing this protocol report 85% reduction in restorative costs over 15-year lifecycles.

Future-forward facilities integrate conductive industrial flooring systems that interact with autonomous vehicles through embedded RFID grids, reducing navigation errors by 74%. Thermochromic systems provide visual temperature warnings at 150°F+ thresholds, while modular interlocking tiles allow targeted component replacement. These innovations transform industrial flooring from passive surfaces to active productivity systems that contribute to operational intelligence and safety benchmarks.

(industrial flooring)

Here are 5 industry-focused FAQs about industrial flooring, incorporating the specified :

A: Industrial flooring refers to durable flooring systems designed for heavy-duty environments like factories, warehouses, and production facilities. These specialized floors withstand chemical spills, impact damage, and heavy machinery loads. Materials like epoxy resins and polyurethane are common for their resilience.

A: Industrial flooring enhances safety by providing slip-resistant, seamless surfaces that reduce trip hazards. Its chemical resistance protects against corrosive substances in production lines, while specialized formulations resist thermal shock and mechanical stress from heavy equipment.

A: Racquetball and squash factories need specialized flooring to endure high-impact rubber molding processes and court surface production equipment. Customized slip resistance prevents accidents around chemical mixing areas, while joint-free designs accommodate precision manufacturing machinery producing sports flooring components.

A: Top industrial flooring offers extreme durability against abrasion, chemicals, and thermal cycling. Critical features include seamless application to prevent contamination traps, static-dissipative options for electronic manufacturing safety, and certifications for food-grade environments in production facilities.

A: Maintenance requires regular mechanical scrubbing with pH-neutral cleaners to remove rubber and adhesive residues. Surface integrity requires resealing high-traffic zones annually, while immediate spill containment prevents material degradation from court-production chemicals like volatile solvents.

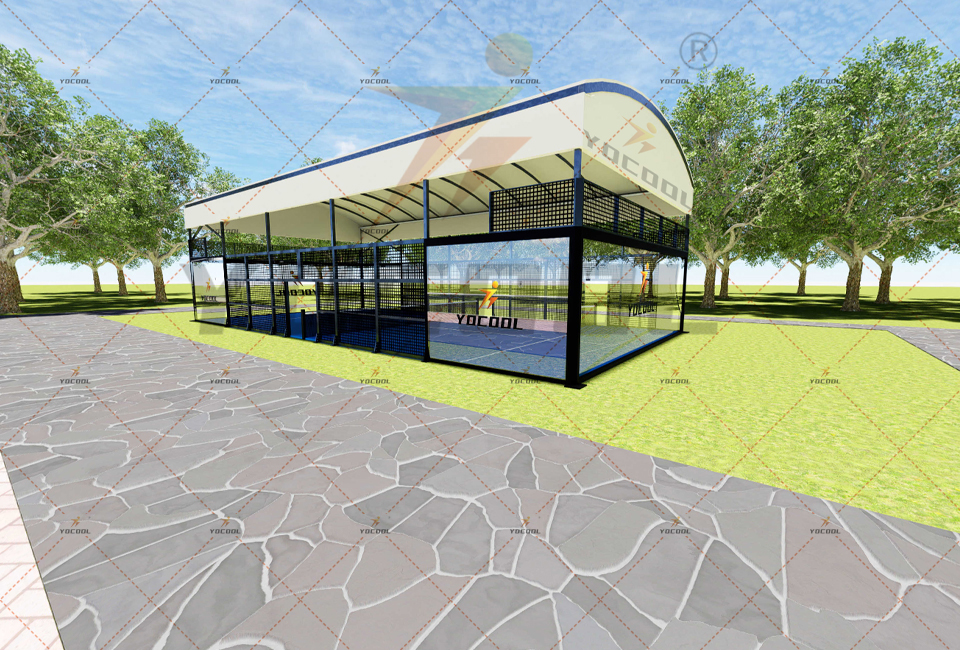

Premium Padel Court Solutions for Clubs & Resorts | Durable & Panoramic Design

High-Quality Padel Court Solutions for Clubs & Homes

Premium Paddle Tennis Rackets for All Paddle Court Types

High-Quality Padel Court Solutions for Sports Facilities & Clubs

Premium Padel Courts: Custom Designs & Panoramic Views

Premium Paddle Racquet | High-Control Lightweight Design